There is a close relationship between the Trapezoidal roof sheet machine and the quality of the color steel plate. The quality of color steel plate is affected by many aspects such as raw materials, production process, equipment performance and operation, and metal Trapezoidal roof sheet machine plays a key role in it.

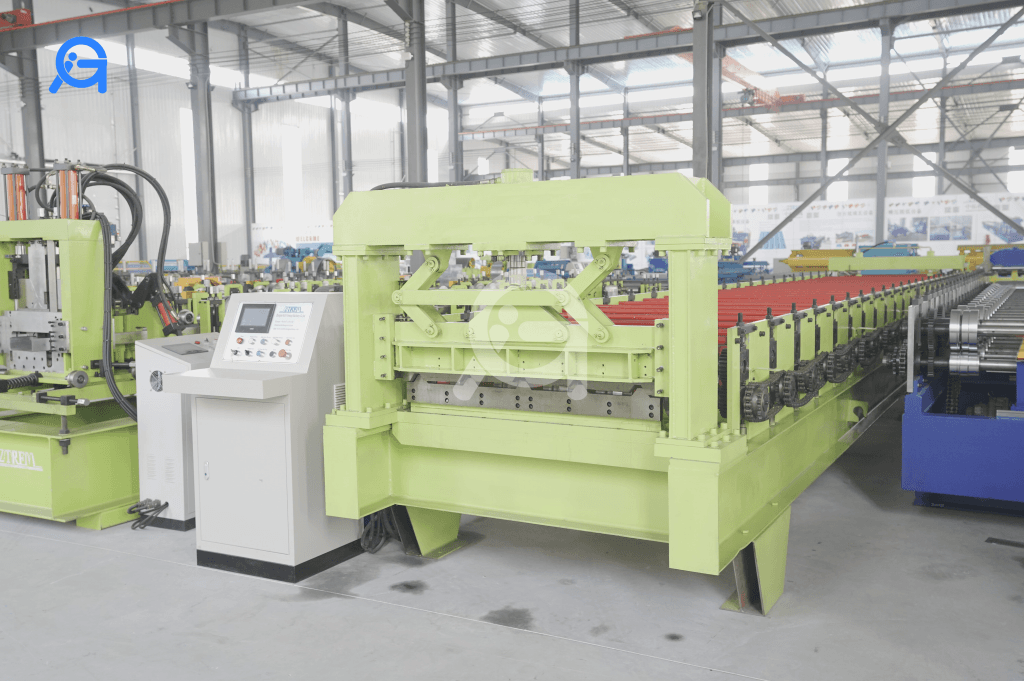

First of all, Trapezoidal roof sheet machine is the core tool of Trapezoidal color steel plate production. By cold forming the color coated steel plate, it is processed into a color steel plate with a specific cross-section shape. In this process, the performance of the equipment directly affects the processing accuracy, plate quality and production efficiency of the color steel plate. For example, if the equipment is highly accurate and can precisely control the pressure and waveform, the color steel plate produced will have better dimensional accuracy and shape consistency.

Secondly, the maintenance status and operation technology of the machine will also affect the quality of Trapezoidal color steel plates. If the equipment is properly maintained, such as maintaining the finish and uniform wear of the roller wheel, then the surface of the formed color steel plate is not prone to scratches or wear marks. In addition, the technical level of the operator is also very important, and they need to adjust the process parameters according to the performance and production requirements of the equipment to ensure the molding quality and production efficiency of the color steel plate.

In addition, the design and manufacturing technology of the machine also affects the long-term performance of color steel plates. The advanced design concept and high standard manufacturing process can ensure the long-term stable operation of the equipment and reduce the failure rate, thus ensuring the production quality and supply stability of the color steel plate.

All in all, high-quality Trapezoidal color steel plate making machine can improve the processing accuracy, surface quality, structural performance and production efficiency of color steel plates, while poor equipment performance may lead to a decline in the quality of color steel plates, affecting engineering quality and safety. When selecting and using cold forming equipment, attention should be paid to its performance, maintenance and use of technology to ensure the production of high-quality color steel plates.

It is important to select a high-quality machine, but don’t forget to carefully maintain the cold roll forming machine in the subsequent use of the machine. Finally, if you want to buy a machine but are not sure which supplier to buy from, you can visit our factory and our staff will provide you with a satisfactory design solution.