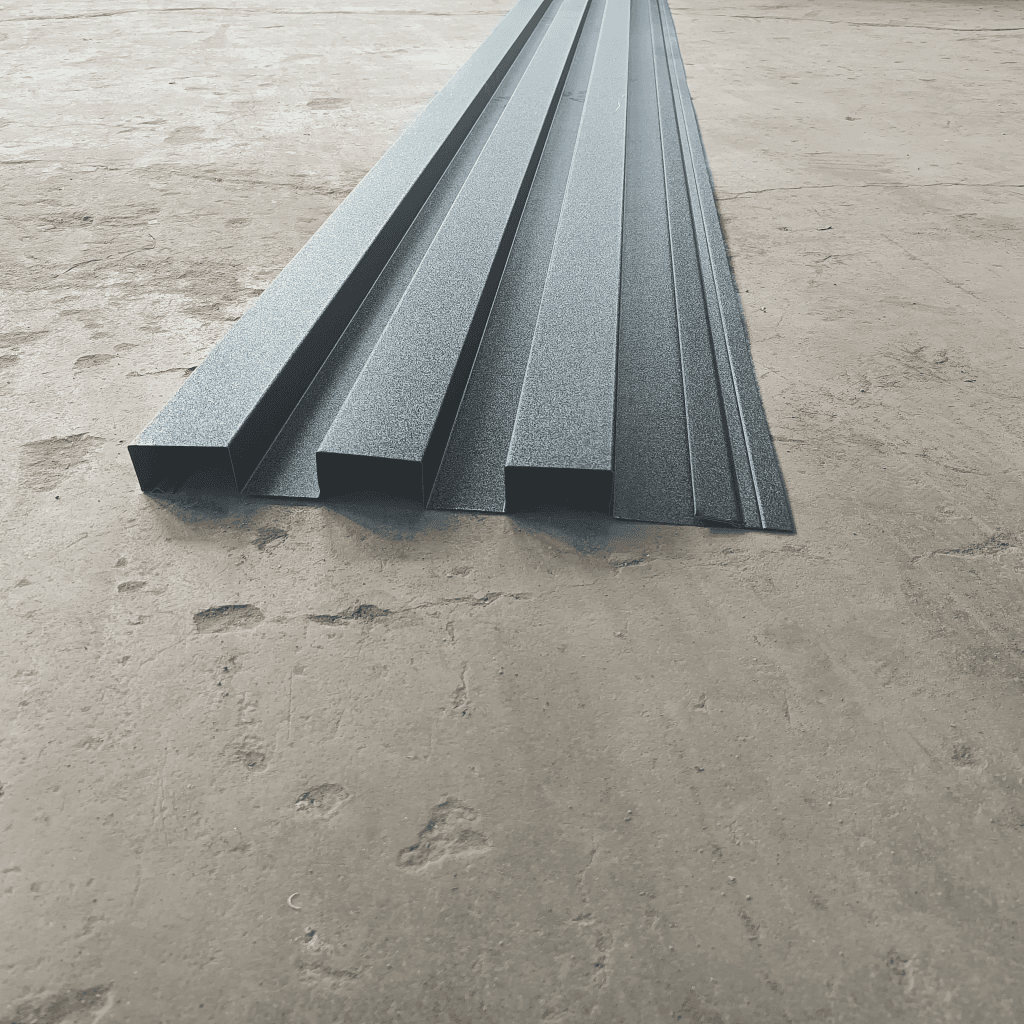

Metal cladding panels, crafted by wall cladding machine , are extensively utilized for the adornment and preservation of building facades. These panels feature a 90-degree angle, enabling them to be mounted horizontally on the exterior walls, offering comprehensive coverage and robust protection. Typically crafted from galvanized steel, aluminum, or other weather-resistant metal materials, the 90-degree wall cladding panels boast the following attributes and benefits:

Strength and Longevity: The metallic composition of these panels confers exceptional mechanical strength and durability, capable of withstanding diverse weather conditions and external impacts, thereby prolonging the building’s lifespan.

Corrosion Resistance: thanks to galvanizing or other surface treatments, these panels exhibit high corrosion resistance, ensuring stable performance even in harsh environments.

Aesthetic Appeal: The metal cladding panels can undergo various surface treatments such as painting or coating, providing a rich array of colors and textures to enhance the building’s visual appeal.

Thermal Insulation: Incorporating insulation materials within the panels improves the building’s thermal efficiency and reduces energy consumption.

Ease of Installation: The 90-degree horizontal panels are designed with a specialized connection system, including fasteners or screws, facilitating quick and effortless installation, which in turn cuts down on construction time and costs.

Low Maintenance: The inherent properties of metal make the 90-degree wall cladding panels easy to clean and maintain, ensuring they retain their pristine appearance over an extended period.

Application

The 90-degree horizontal hanging metal wall cladding panel is mainly used in the exterior wall decoration and maintenance of various buildings, such as residential buildings, commercial buildings, industrial plants, schools, hospitals, etc. Especially in areas that require horizontal coverage and protection, such as the side walls of the building, the edge of the roof, around the window frames, etc., 90-degree horizontal panels provide effective waterproof and wind protection while enhancing the visual effect of the building.

Production and processing

The production of 90 degree wall cladding panel is usually made by cold forming machine, which bends the metal plate into a 90 degree angle through a precise mold, and then performs subsequent processing such as cutting and surface treatment as required. This production method can ensure the dimensional accuracy and shape consistency of the plate to meet the requirements of building construction.

Below some pictures of wall cladding roll forming machines for your reference.