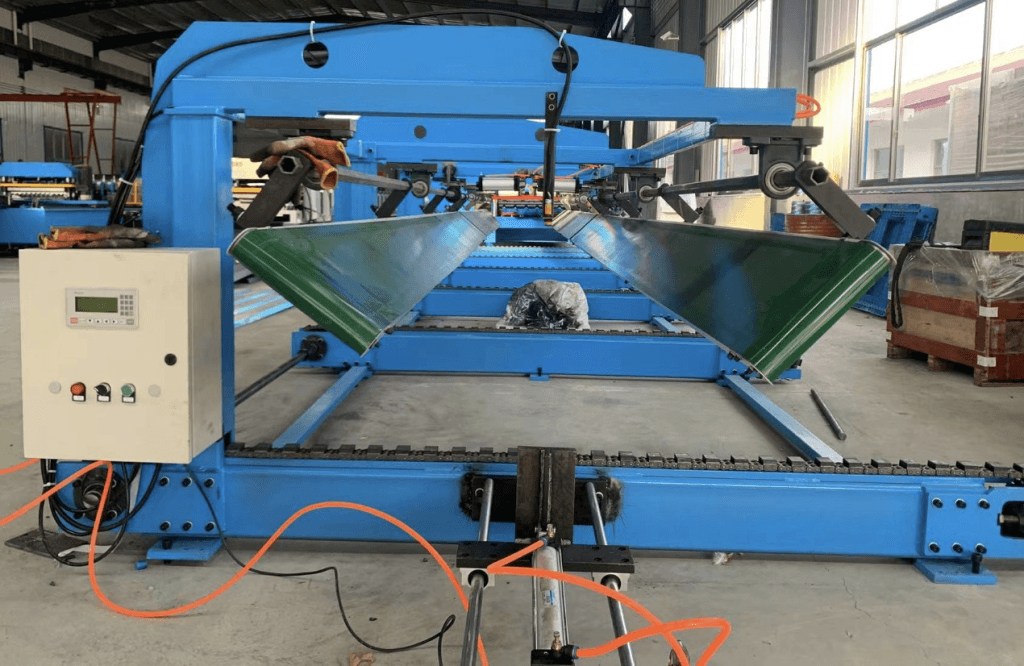

When we talk about collecting production tables, there are two types. Generally speaking, our company provides manual 3m simple stacker. If the customer needs a high working speed machine, we can provide automatic stacker. This automatic stacker was chosen by our Guatemalan customer in the case of our high speed glazed forming machine. Next let’s talk about the features of automatic stacker.

1.The frame of the stacker uses more thicker steel welded. It is more strong and can bear the weight so much;

2.We have a conveying platform with a pvc surface. This soft material can play a role in protecting the paint;

3.There are several lines of rubber block to collect the product, in order to prevent the product falling and hurting the surface;

4.There is a pneumatic system to achieve a neat stack of color steel plates. Convenient for subsequent transportation and use.

Automatic stacker instead of manual simple stacker, can reduce the labor intensity and error rate of operators, improve the safety of production site and production efficiency. Especially for some countries with expensive labor costs, it can reduce labor costs.

The main difference between automatic stacker and manual receiving rack is the mode of operation, work efficiency and safety. Customers can choose according to actual situation.