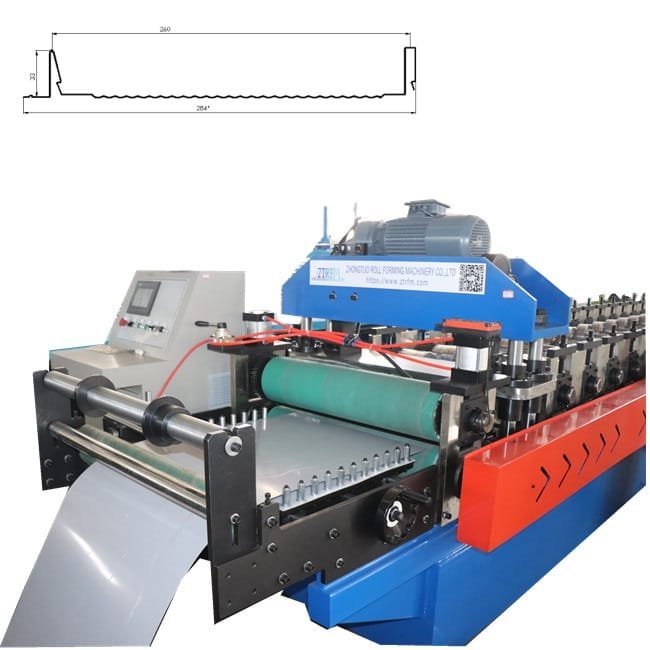

The standing seam forming machine offers a versatile solution for manufacturing standing seam roofing panels, providing excellent performance, precision, and adaptability. With options for mechanical seam, snap-lock, and nail strip/fastener flange profiles, this machine stands out for its ability to adjust width automatically and produce custom embossing patterns. Designed for flexibility and long-term durability, this machine is ideal for various roofing applications.

Key Features of the Standing Seam Forming Machine:

- Automatic Width Adjustment: Adjust the panel width with PLC control, accommodating both narrow strips and wide coils to meet specific requirements.

- Customizable Embossing Patterns: Includes embossing rollers for unique bottom rib designs tailored to your needs.

- Precision Engineering: Equipped with a linear motor for accurate forming processes.

- Durable Rollers: High-quality rollers ensure long-lasting performance.

- Secure Snap-Lock Mechanism: Provides a tight and reliable connection, essential for superior roof performance.

- Optional Side Locking: Offers the choice to enable or disable side-lock functionality, depending on your project.

- Enhanced Profile Aesthetics: Side rollers ensure a flawless and uniform profile shape for a professional finish.

For those seeking cost-efficient options, we also offer fixed-width machines, which are more affordable but lack the adjustable features.

Why Choose the Standing Seam Forming Machine?

This versatile machine is ideal for manufacturers who require flexibility in panel width and design. Its innovative features, such as automatic adjustments and customizable embossing patterns, make it a valuable addition to any production line. Whether for residential or commercial projects, the snap lock forming machine ensures precision, durability, and aesthetic appeal.

For more information about the standing seam forming machine and its capabilities, feel free to contact us anytime.