The roller of our company adopts 45# steel,Cr12, GCr15 or other materials.It is processed by electroplating hard chromium and other processes.This not only prevents abrasion,keeps the roller neat and more beautiful,but also improves hardness and increases the service life of the roller.

The common shaft diameter is 70mm, 80mm, 90mm,and it can be produced according to customer requirements.The shaft is made of 45# steel or 40Cr.The hollow shaft is easy to damage and affect the accuracy of products.So our shafts are all solid shafts which is not easy to damage.

In order to prevent the linear speed of the shaft from being inconsistent with the roller ,we set a key groove on the shaft and the roller. So that the shaft and the roller become a whole to a certain extent and avoid the idling of the shaft.

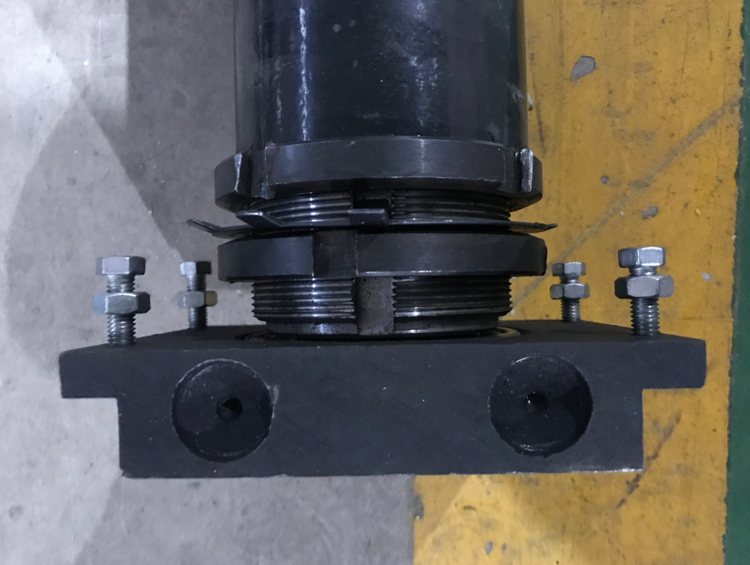

With the aim of preventing the shaft from loosening during operation of the glazed tile forming machine ,we adopt positive and negative turnbuckles,double lock nuts and check mat.

Our spacers are usually made of 45# seamless steel pipe ,which are manufactured by hard chromium plating or boiling black .treatment.The 3-5 mm seamless steel pipe is firm enough to bear the working intensity of rollers.And it can enhance the stability of the machine during operation and increase its service life.

The pull rod used to link the medium-plate on both sides of main roll forming system is also made of 45# seamless steel pipe which is processed by a series of processing such as electroplated hard chrome or boiled black. It has a beautiful appearance and is not easy to rust.The pull rob strengthens the stability of the machine.

In order to avoid paint scratching which is caused by inconsistency in linear speed between the upper roller with the lower roller, we adopt bearings which can support the rotation of the upper and lower shafts to reduce friction in the movement process.

The above is about the content of main roll forming system of glazed tile roofing sheet machine. If you have any questions please contact with us.