Trapezoidal (IBR) roofing sheet machine

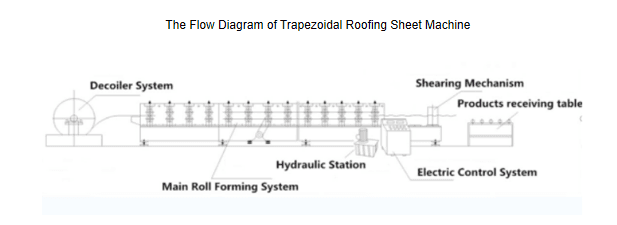

Trapezoidal color steel tile forming machine is one of the main products of our company. The machine processes the steel plate into trapezoidal shape through the cold bending process of roll. The whole production line consists of six parts. As shown in the picture:

Next I will introduce it for you one by one.

Decoiler System

Manual decoiler is a regular and passsive type. Our manual decoiler is equipped with manual wheel and brake, which will not appear the deposition of material.The shrink and expand of core is manual.This type is simple in structure and low in cost.If the speed of decoiling is greater than the speed of feeding, it will lead to accumulation of steel.Our design can avoid this situation.

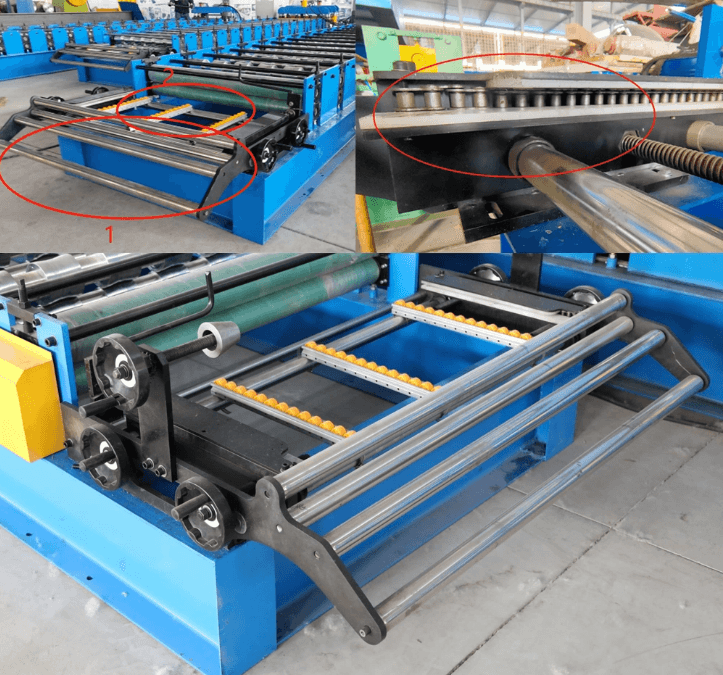

Guide Feeding Device

The four rollers of the feeding port adopt the design of three supports and one pressure, and the rollers can be rotated, so that the friction between the steel and the rollers can be reduced during the feeding process and the steel surface can be avoided.The top roller also prevents the steel from sticking up.

There are three rows of rolling rubber rollers, which also avoid material scratches.

The side has chain links and nylon brackets, which protect the steel from scratches. The upper nylon plate has a partial missing, which is convenient to observe the position of the steel when feeding.

Insert screws also prevent scratches to the steel. The handwheel on the side can be used to adjust the feed width for precise feeding.

The steel plates on both sides of the feeding device are formed in one body and are not easy to be damaged. The hollow design of the steel plate also reduces the weight of the IBR roofing sheet machine.

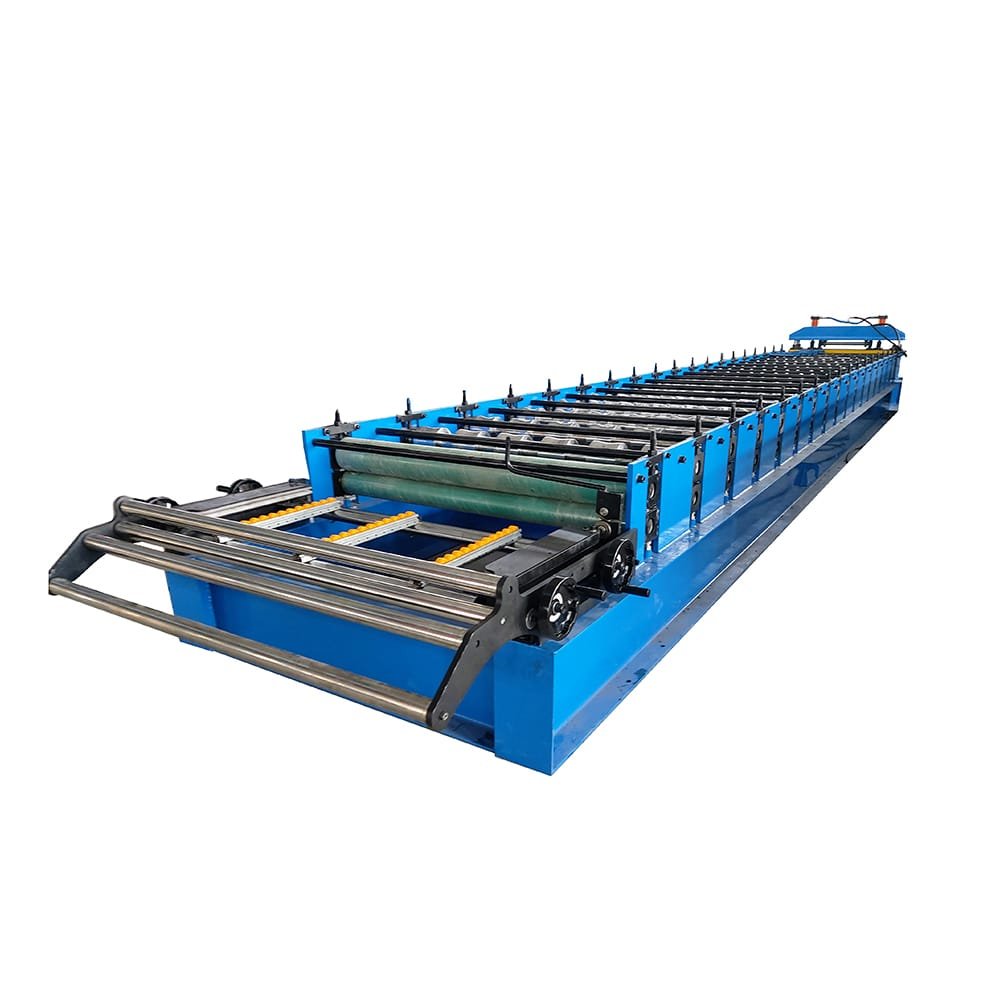

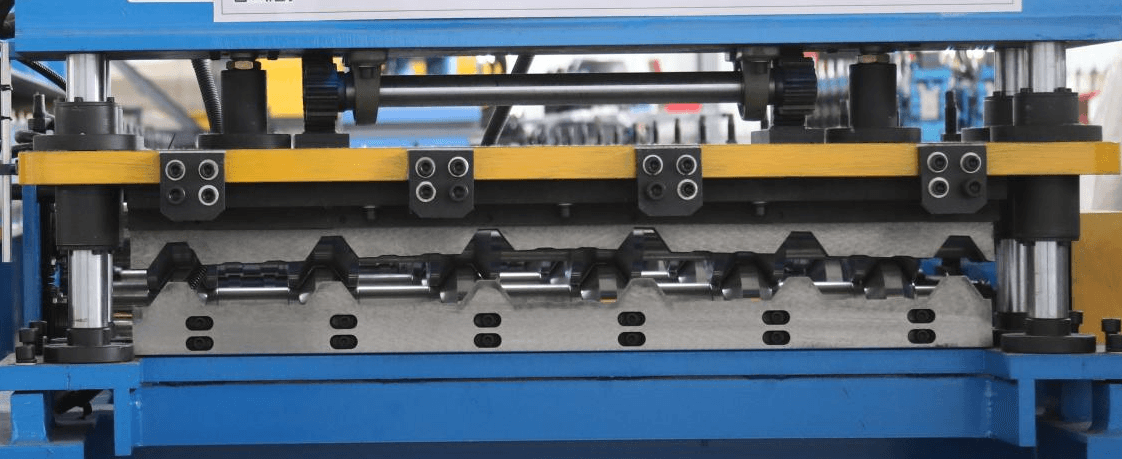

Main Roll Forming Machine

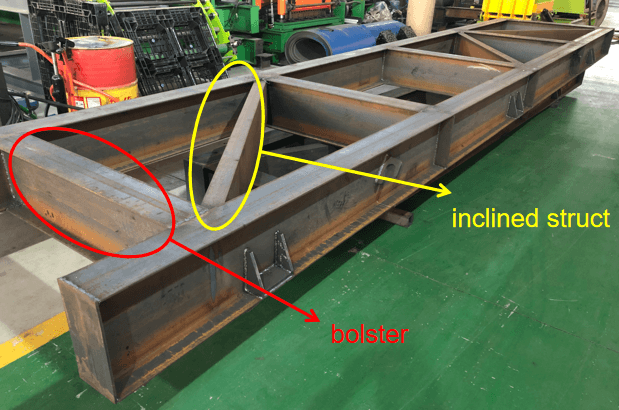

1.Our frame is welded by 400# H-shaped steel. The H-shaped frame and the design of the inclined strut and bolster increase the strength of the frame. The strength of the steel, its own weight and structure are important factors in keeping the frame stable and reliable. In addition, the lifting ear, lifting hole and lifting hole are convenient for loading and unloading.

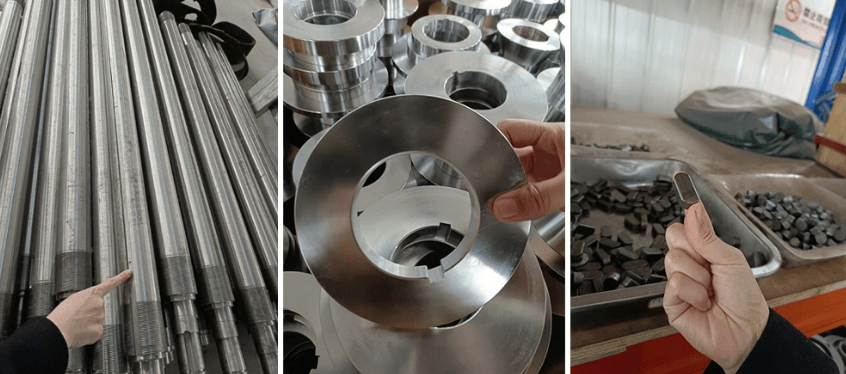

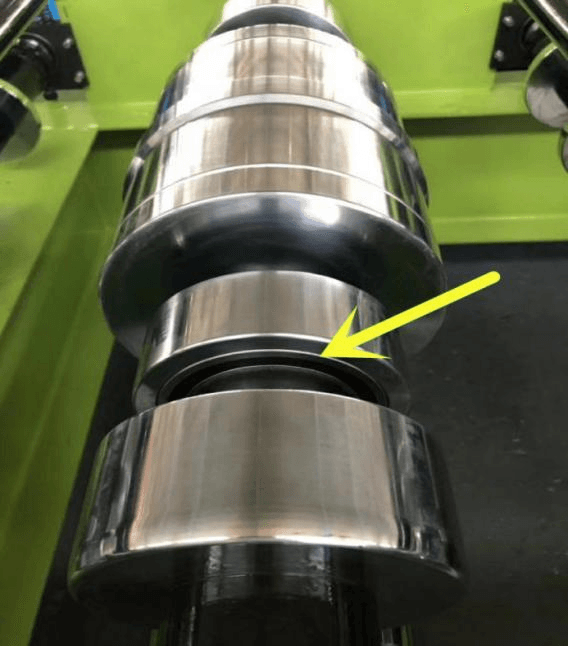

2.Our rollers are generally made of 45# steel processed by a series of processes such as electroplating hard chromium.The roller has high hardness, long service life.It also can prevent rust, and keep the product clean.

3.Common sizes of the shaft are 70mm which can be produced according to your requirements. The material is 45# steel. Our shafts are solid and not easily damaged.

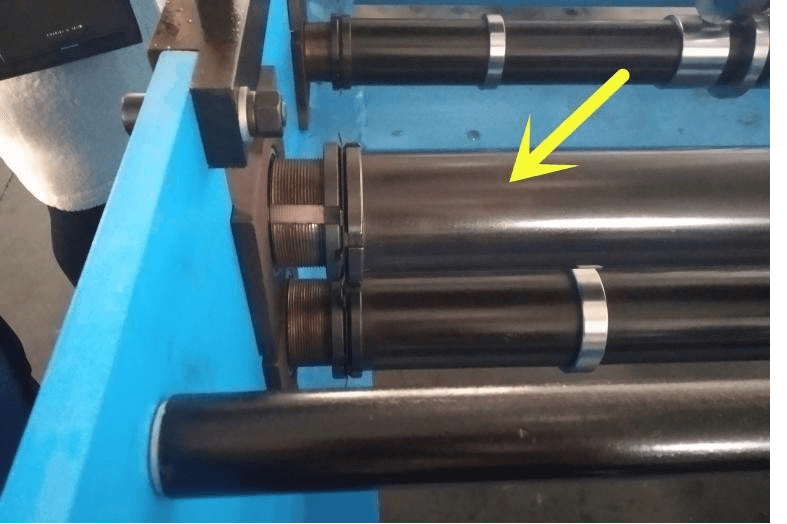

4.The shaft and roller are arranged by the key grooves to prevent the linear speed of the shaft from being inconsistent with the roller, which will cause displacement.

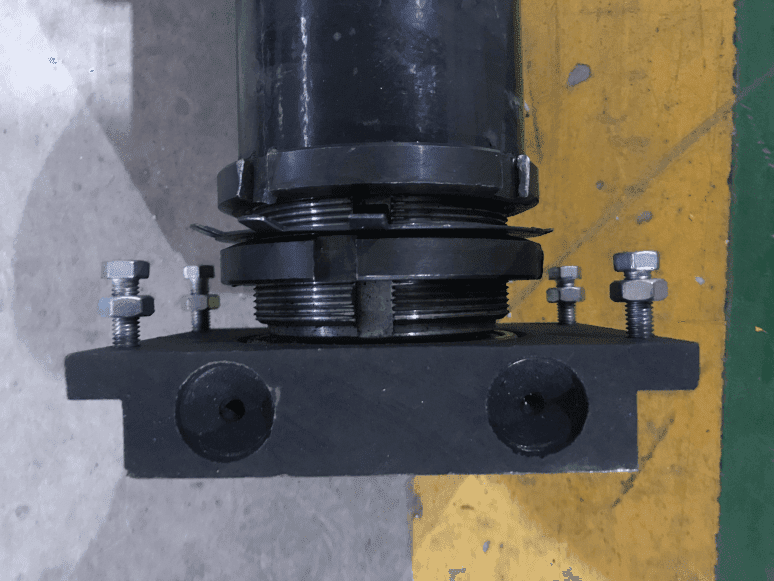

5.The design of positive and negative turnbuckles,double lock nuts ,and check mat can prevent the shaft from loosening during machine operation.

6. Spacer is made of 45# seamless steel pipe, which is strong enough to ensure the normal operation of the IBR roof tile roll forming machine. After boiling black processing, not easy to rust.

7. The existence of bearing can avoid paint scratches caused by inconsistent line speeds.

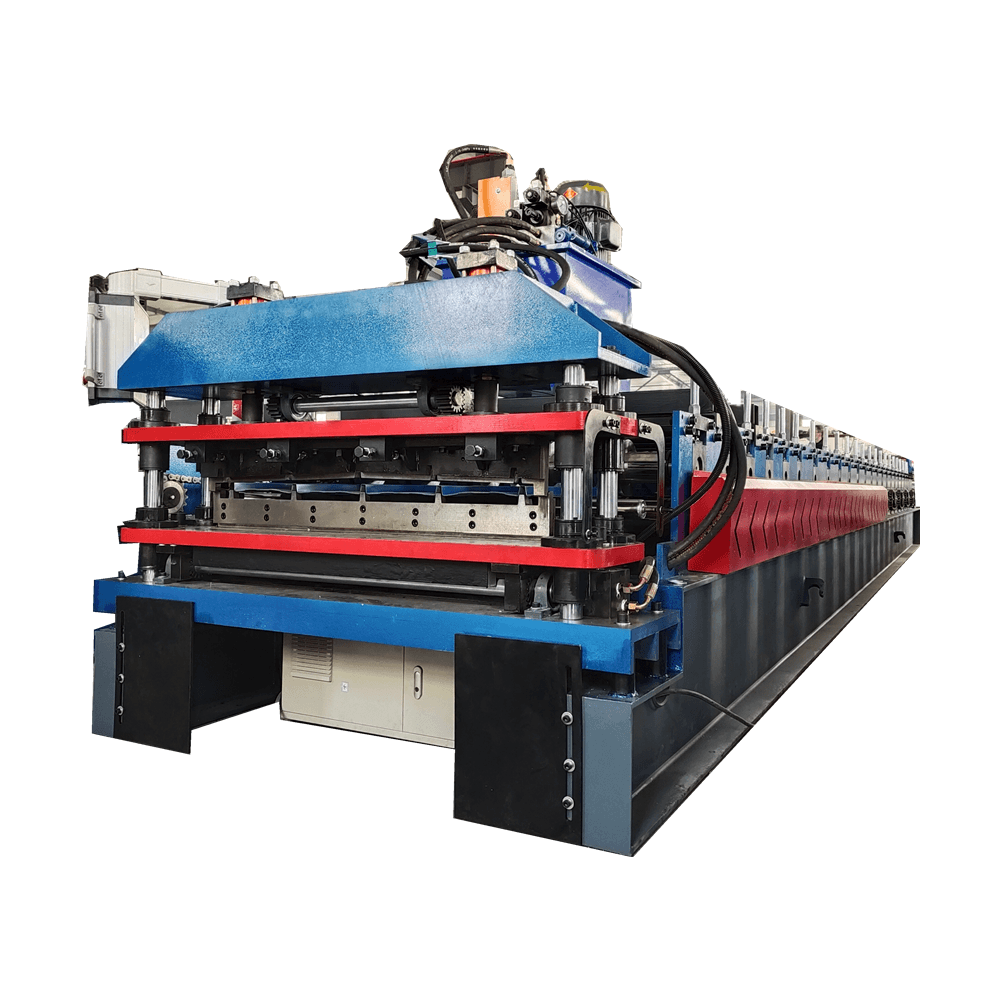

Hydraulic Shearing

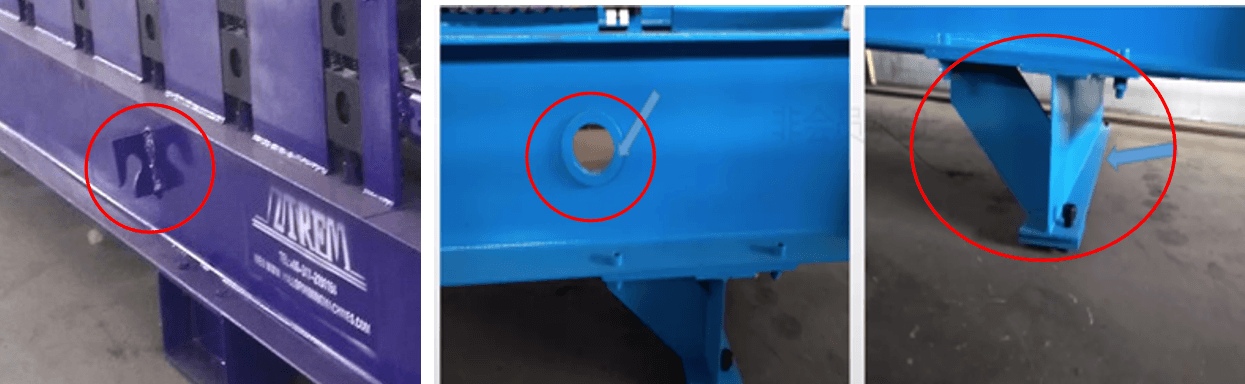

The blade material is generally Cr12.The upper blade is inserted into the frame.And we adopt two lines of bolts and nuts to fix each blade,which has high stability.

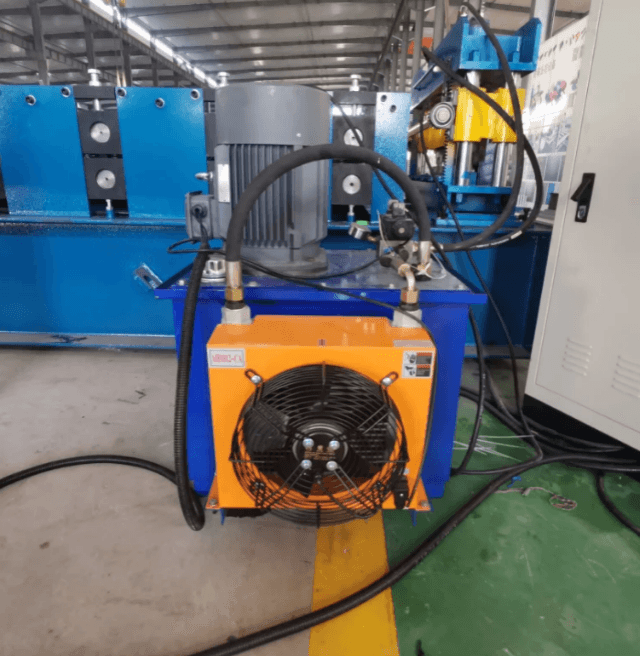

Hydraulic Station

Hydraulic Station provides the power for the shearing mechanism.We adopt the oil of 46# and large valve with high cost which is not easy to block.And the power commonly includes 3kw, 4kw, 5.5kw.The capacity of the fuel tank is usually 80 liters or 110 liters.We are equipped with air cooling devices to prevent the hydraulic oil from overheating and affecting the operation of the machine.The motor of hydraulic station is a Chinese standard brand with good quality and its service life is more than 10 years.

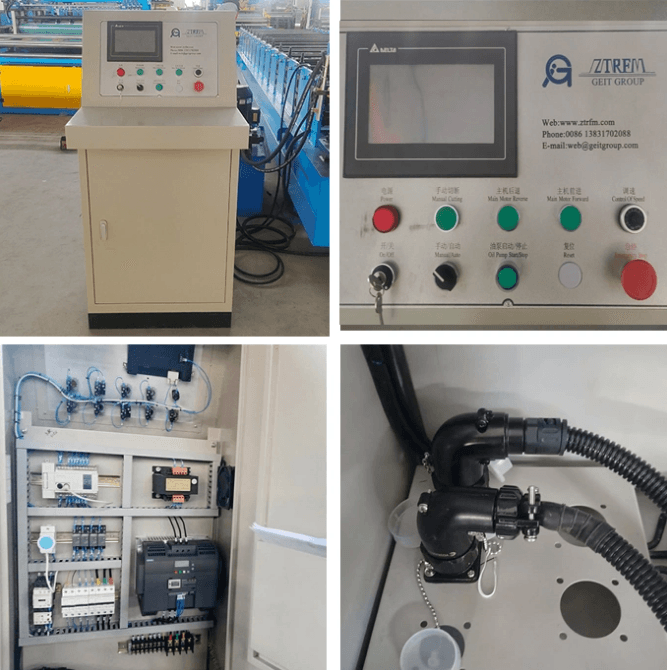

Electric Control System

There are touch screen and manual buttons to control the movement of the machine and the length of the sheet.The regular language of the panel is Chinese or English.We can also customize other languages according to your needs.

Electric Control System is equipped with internationally well-known brands such as Delta, Schneider,Siemens.If it is damaged,it is convenient to repair. In addition,the electronic contacts in our manual buttons are silver, which has good conductivity, accuracy and long service life.

We adopt Omron counters with accurate counting measurement and good quality. Each wire marked with a number or letter is installed neatly.

The aviation plug used to integrated these wires together is inside a box to protect it.And it is convenient for your use. You can choose to install remote operating system of PLC. So that our engineers will debug it for you remotely when there is a problem with the machine.

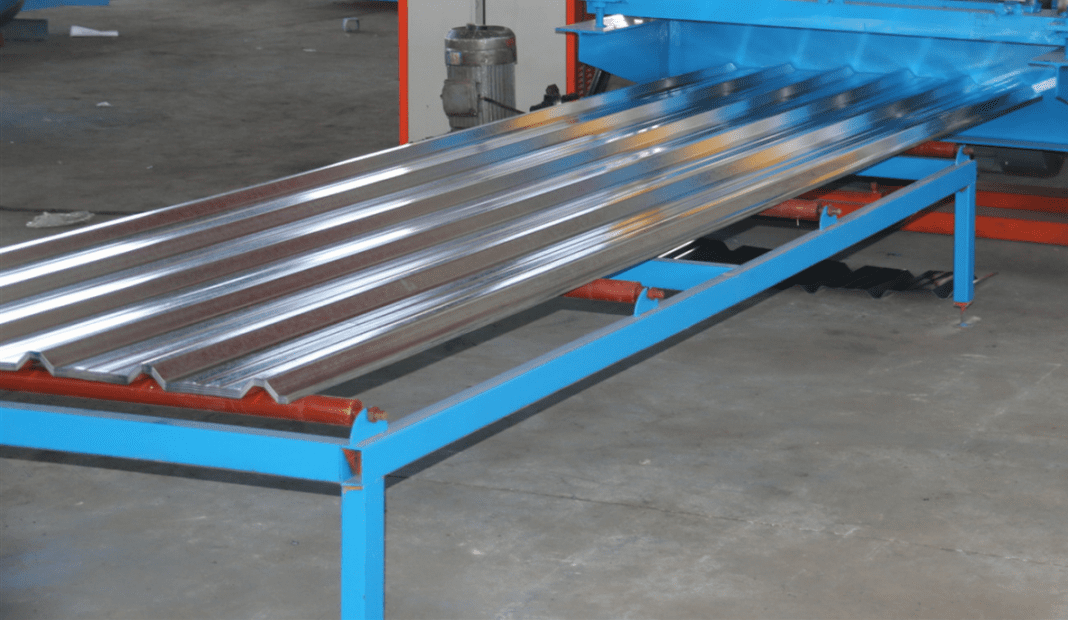

Products receiving table

The regular type is a 3m manual collection table with rollers to protect the steel.Automatic stacker can realize full-automatic receiving steels to save labor.In order to prevent the steel from falling from the height and affect the beauty of the steel,we also have liftable automatic stacker with double layer roofing sheet machine and lifting platform,which can adapt to discharge outlets with different heights.