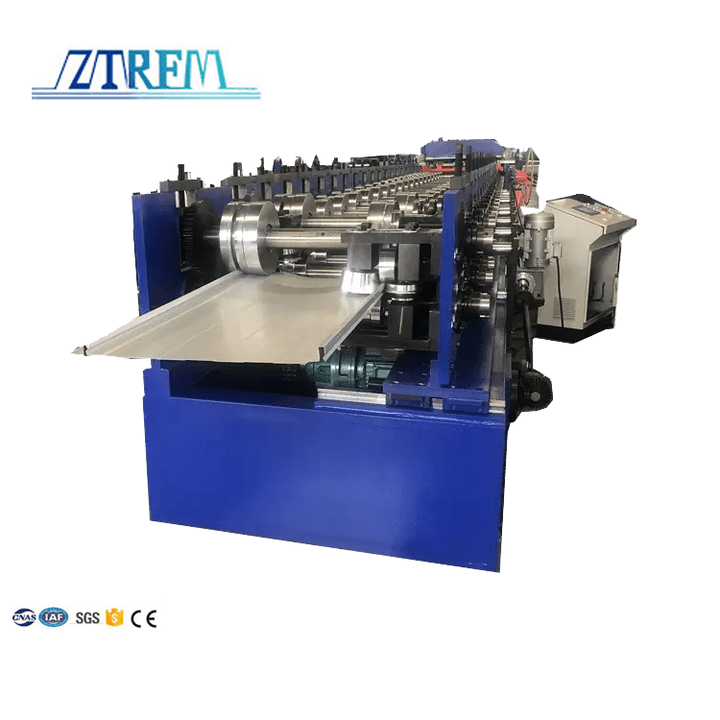

The soffit panel roll forming machine is an advanced piece of industrial equipment designed for the precise and efficient manufacturing of soffit panels. These panels are widely used in roofing and siding applications for both residential and commercial buildings. Our machine offers superior performance, delivering consistent panel dimensions, smooth finishes, and excellent durability.

Engineered with cutting-edge technology, this roll forming machine automates the entire production process—from coil feeding to panel cutting—minimizing material waste and ensuring consistent quality. Its robust construction, user-friendly interface, and high production speed make it an ideal solution for soffit panel manufacturers aiming to increase productivity and reduce labor costs.

Key Features of the Soffit Panel Roll Forming Machine

1. Precision Roll Forming System

Equipped with hardened rollers and shafts, the machine ensures accurate and uniform panel shaping.

Maintains precise dimensions and clean-cut edges, providing panels with a flawless finish.

Supports custom panel sizes according to specific project requirements.

2. High-Speed and Efficient Operation

Advanced servo motor technology enables rapid production without sacrificing quality.

Automatic coil feeding and cutting system reduces downtime and boosts efficiency.

Continuous roll forming process allows for large-scale production with minimal interruptions.

3. Durable and Reliable Construction

Built with heavy-duty steel frames for stability and longevity.

Corrosion-resistant coating enhances the machine’s durability, even in demanding industrial environments.

Components from reputable brands ensure long-term, reliable performance.

4. User-Friendly Control Panel

The machine features an intuitive PLC control system with a touchscreen interface.

Easy-to-use software allows operators to set panel lengths, quantities, and production speeds with precision.

Real-time monitoring ensures smooth operation and quick troubleshooting.

| Parameter | Details |

|---|---|

| Machine Type | Soffit Panel Roll Forming Machine |

| Material Thickness | 0.4mm – 1.2mm |

| Material Width | 200mm – 600mm |

| Forming Speed | 15 – 25 m/min |

| Control System | PLC with Touchscreen |

| Drive System | Hydraulic / Electric |

| Cutting Method | Hydraulic or Servo Cutting |

| Power Supply | 380V, 50Hz, 3-phase |

| Roller Material | High-grade steel (Cr12) |

| Coating Treatment | Hard Chrome Plated |

Advantages of Our Soffit Panel Roll Forming Machine

✔️ 1. Increased Productivity

Our machine operates at high speeds, enabling you to produce more panels in less time. This increases your daily output and maximizes profitability.

✔️ 2. Consistent Quality

Thanks to its precision rollers and automated cutting system, the machine ensures uniform panel dimensions with every production cycle. This consistency improves the overall quality of the final product.

✔️ 3. Reduced Material Waste

The optimized feeding and cutting mechanism reduces scrap material, helping you save on production costs while maintaining a sustainable workflow.

✔️ 4. Low Maintenance Requirements

Designed with durability in mind, the machine requires minimal maintenance, reducing downtime and repair costs.

Applications of Soffit Panels

The soffit panel roll forming machine is perfect for producing panels used in a variety of construction projects, including:

Residential Roofing & Siding: Provides proper ventilation and enhances the aesthetic appeal of homes.

Commercial Buildings: Adds protection and a sleek finish to eaves and overhangs.

Industrial Projects: Durable soffit panels designed for harsh weather conditions and long-term performance.