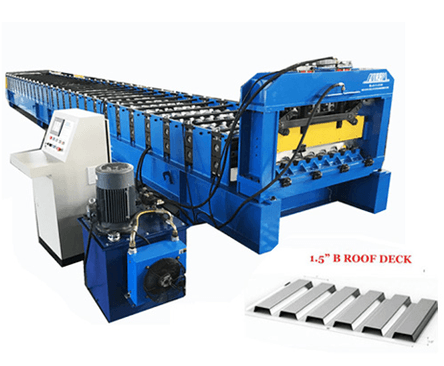

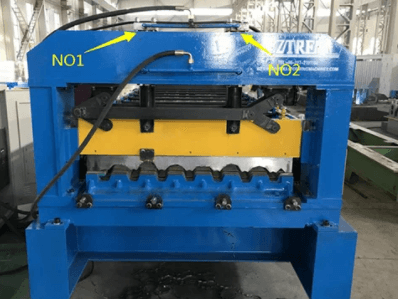

1.5” type B roof deck roll forming machine

The 1.5″ B Deck Roll Forming Machine, also known as Type B Roof Deck Machine or wide rib metal deck machine.

1.5” type B roof deck is a high-performance structural roof deck. With a 1.5-inch depth, it offers exceptional strength and stability, making it ideal for supporting various roofing materials. Its wider rib profile provides more space for insulation, enhancing energy efficiency and thermal performance.

Perfect for commercial and industrial roofing projects, 1.5″ B Deck is widely recognized for its cost-effectiveness, ease of installation, and compatibility with a range of roofing systems. Choose B Deck roofing for a reliable, long-lasting solution that meets modern building

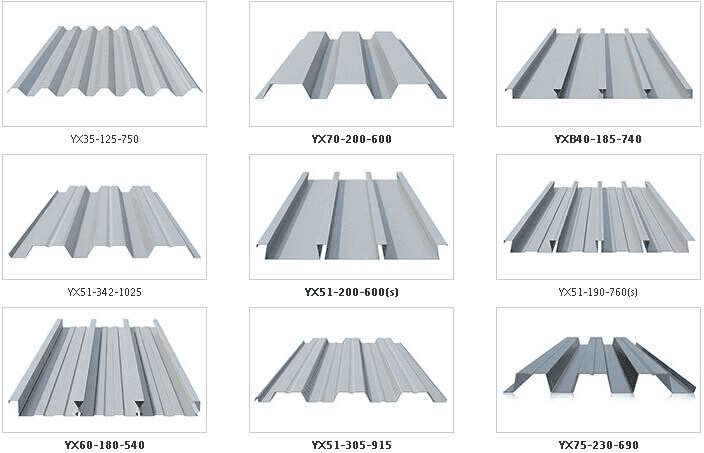

Floor deck roll forming machine, mainly used in steel structures such as power plants, automobile exhibition halls, airports, railway station, stadiums, etc. The floor deck is used to replace the floor design, with concave and convex points on the layout to increase the contact area with cement.

Floor deck features: light weight, high strength, large bearing capacity, good earthquake resistance, simple construction and convenient assembly.

Common type of floor deck:

These are some types, commonly used in some North American countries. Our company’s floor deck forming machine have been exported to New York, Florida, Texas, California as so on.

Raw material:Galvanized coils yield strength till 550 Mpa

Material thickness:16-22gauge ( 0.8-1.5 mm)

Machine frame:400 H beam steel welded

Roller fixer:Middle plate (thickness 20mm)

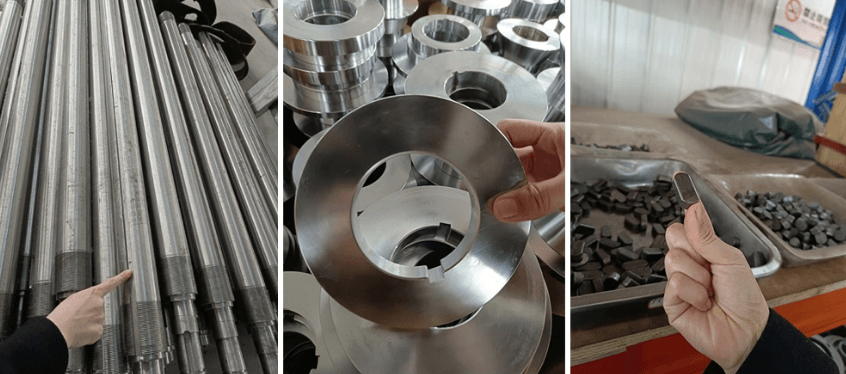

Material of rollers:Gcr15 quenching treat HRC58-60

Forming stations:28 roller stations

Diameter of shafts:φ 95 mm

Material of shafts:45# steel precision-machined

Forming speed:0-15 m per minute

Voltage:480 v 60 hz 3 phase or as request

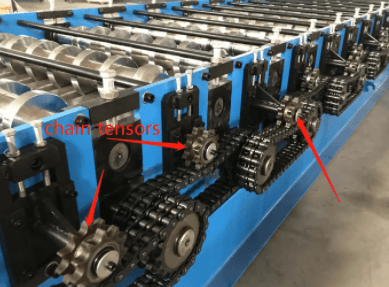

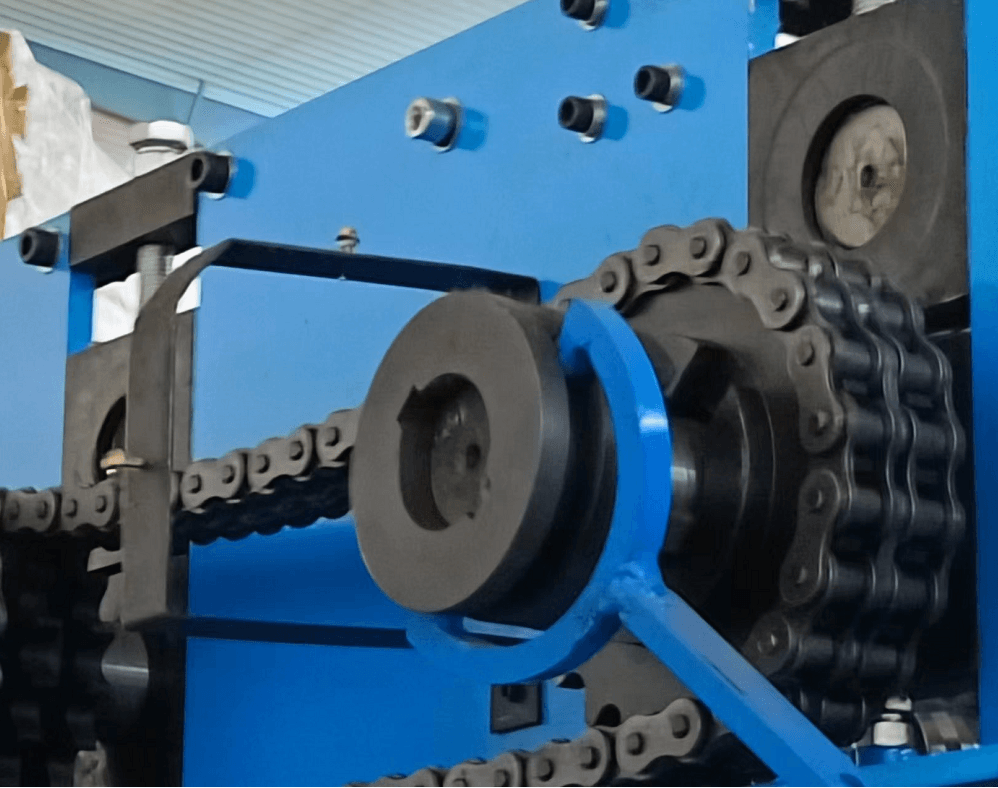

Transmission way:Gear and 2 inches double chain with chain tensors

Cutting blade material:Cr12Mov quenched treatment to improve hardness

Cutting type:Hydraulic cutting

Dimension of the machine:15000 х 1850 х 1500 mm

Weight:about 15.5 t

Workflow: decoiler-feeding material–roll forming-cutting-decks stacker

Next, I will introduce the configuration of each part of the machine in detail for you.

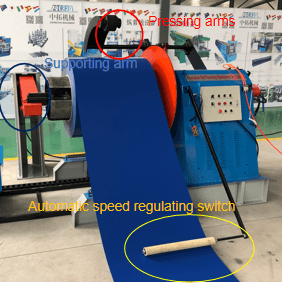

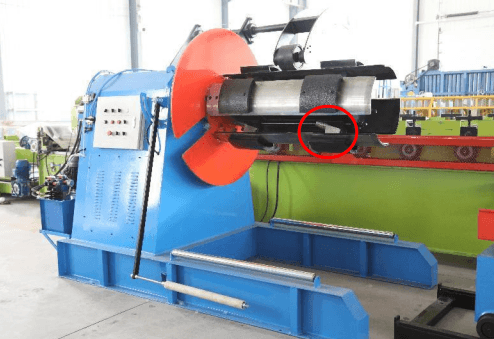

12 tons hydraulic decoiler with loading car:

Hydraulic decoiler is an active type, which can automatically start or stop working by the automatic speed regulating switch according to main forming system speed. It can be operated by one person. Save labor. This type is more expensive and needs more space to place it.

We add a pressing arm to the decoiler to ensure steel coil does not bounce. The supporting arm is used to the bearing capacity of the decoiler so as to place heavier steel coils.

The baffle is provided with a groove. So that when the steel coil is hoisted by a sling, it can be conveniently fetched out. The design of four circular arc arms will keep the coil in shape than square arc arms.

The combination of guide pillar type loading car and hydraulic decoiler can basically realize automation. Guide pillar loading car has large bearing capacity, which can carry the weight of 12 tons of steel coils.

Guide Feeding Device

The four rollers of the feeding port adopt the design of three supports and one pressure, and the rollers can be rotated, which can reduce the friction between the steel and the rollers during the feeding process and protect the steel surface. The top roller also prevents the steel from sticking up. There are many rows of rolling rubber rollers, which also avoid material scratches.

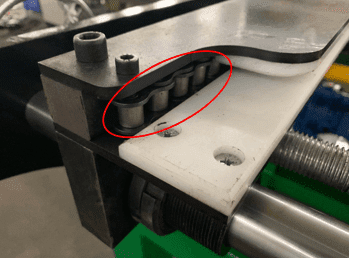

The side has chain links and nylon brackets, which protect the steel from scratches. The upper nylon plate has a missing, which is convenient to observe the position of the steel when feeding. Insert screws also prevent scratches to the steel. The handwheel on the side can be used to adjust the feed width for precise feeding.

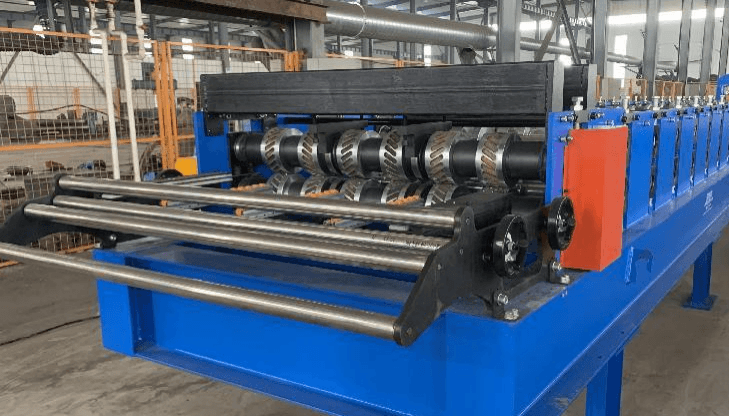

Main Roll Forming Machine of floor deck forming machine:

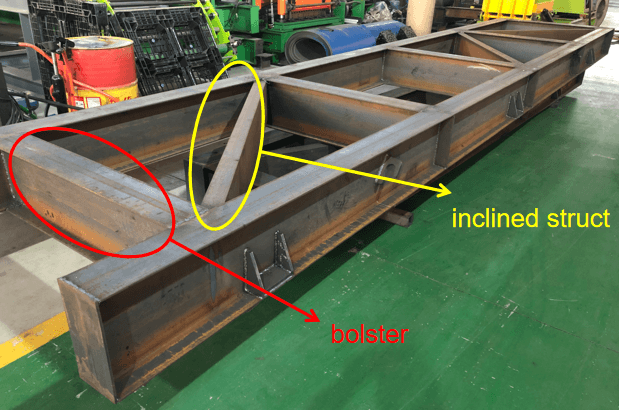

1.Our frame is welded by 400# H-shaped steel. The H-shaped frame and the design of the inclined strut and bolster increase the strength of the whole frame. The lifting ear, lifting hole and lifting foot are convenient for loading and unloading. When the floor of the factory is not smooth enough, the operator can adjust the height of the lifting foot to balance it.

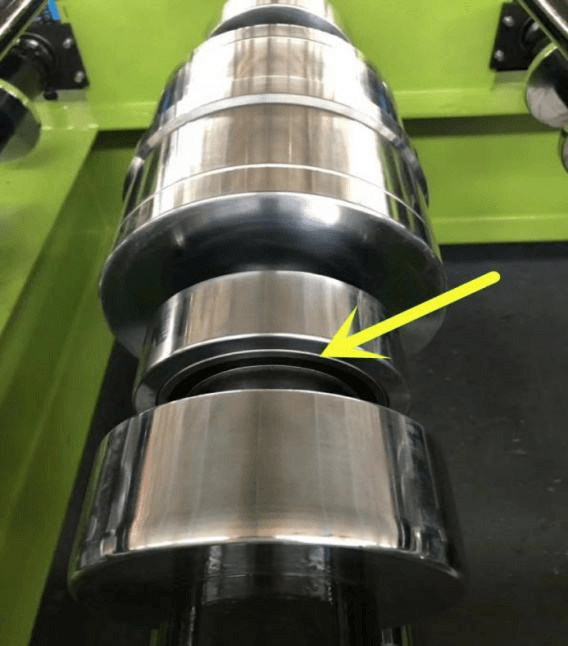

2.Our rollers are made of Gcr15 quenching treat HRC58-60 with high hardness and long service life. It also can prevent rust.

3.The diameter of the shaft are 95mm which can be produced according to your requirements. The material is 45# steel with tempered. We adopt solid shaft, not easily damaged.

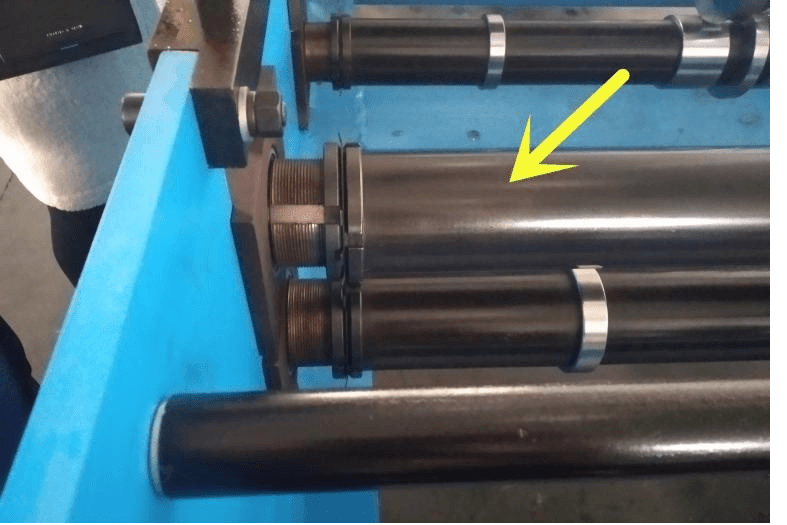

4.The shaft and roller are arranged by the key grooves to prevent the linear speed of the shaft from being inconsistent with the roller, which will cause displacement.

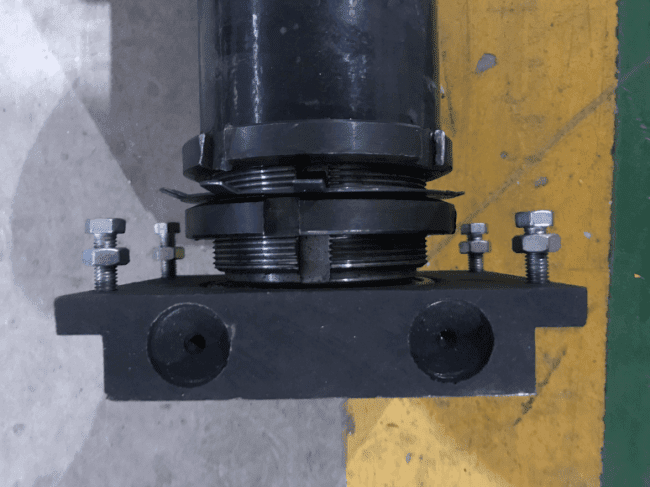

5.The design of positive and negative turnbuckles, double lock nuts, and check mat can prevent the shaft from loosening during machine operation.

6. As we all know,the welded steel pipe may crack during the long-term operation of the machine. So our spacer is made of 45# seamless steel pipe, which is strong enough to ensure the normal operation. After boiling black processing, not easy to rust.

7. Bearing can avoid paint scratches caused by inconsistent line speeds.

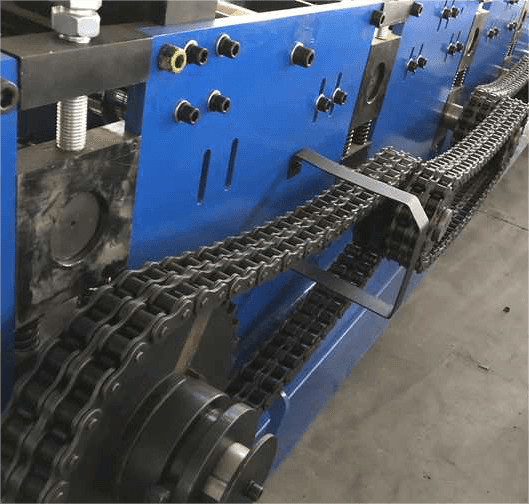

Transmission device

Gear and 2 inches double chain drive, strong and stable. Chain tensors design can guarantee the chain is not loose after long time use.

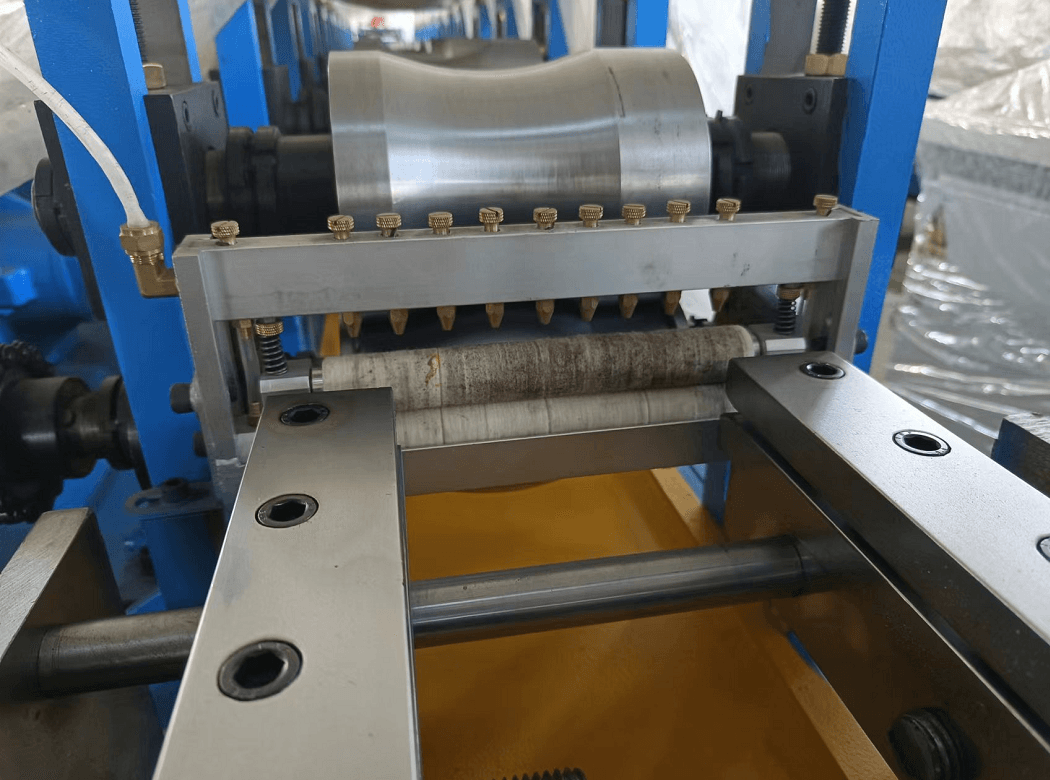

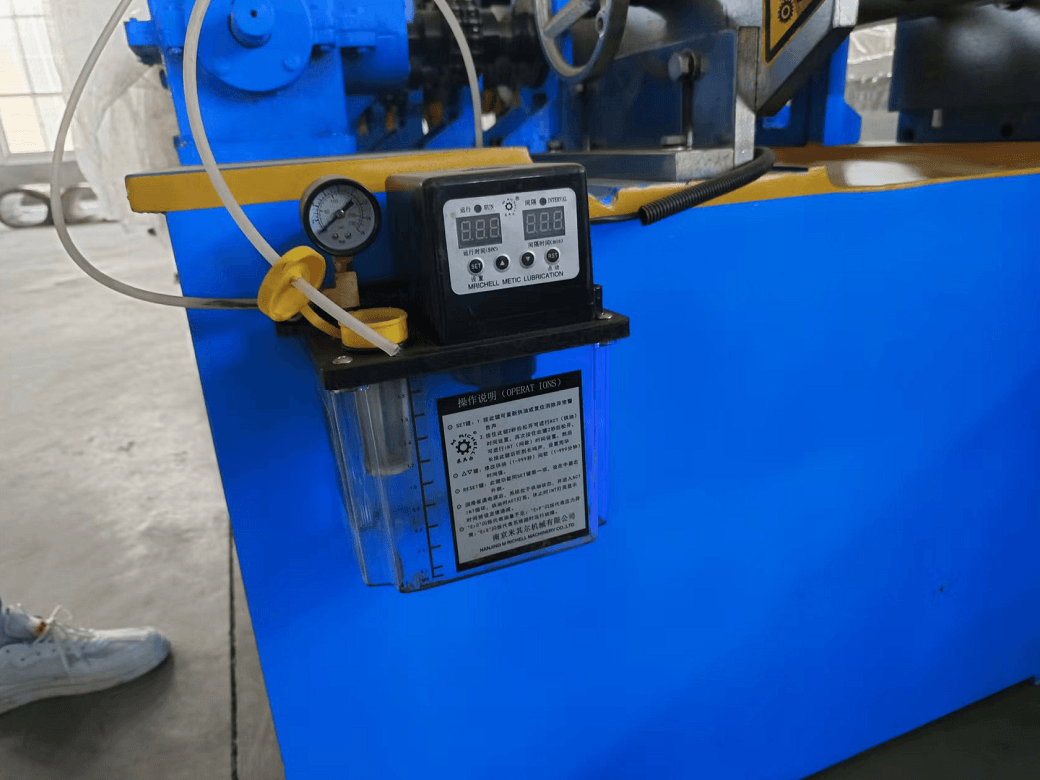

Fuel injection device

Due to the friction between the galvanized sheet and the roller in the operation, sometimes the galvanized sheet is dezincified, resulting in unsightly finished products, so our floor deck machine is equipped with an oil injection device.

Clutch device

Since the embossing wheel moves together in two rows up and down, the speed is faster than that of the previous passive wheel. The first row of the embossing wheel and the first row of the passive wheel are prone to the accumulation of raw materials, so our machines are equipped with clutches.

Hydraulic cutting device

The cutting blade material is Cr12Mov quenched treatment to improve its hardness. Besides, we adopt double oil cylinder 7.5kw motor more stable than single oil cylinder. So the cutter can cut 1.5mm thickness material easily.

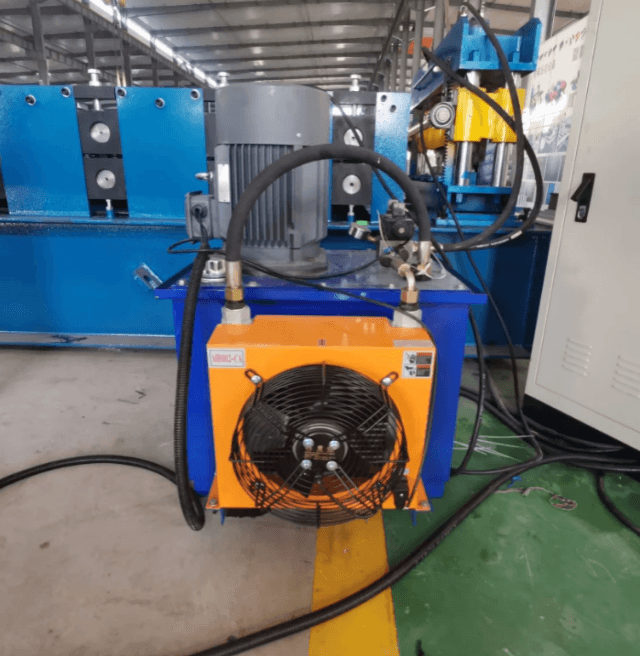

Hydraulic Station with air cooling device

We adopt the oil of 46# and large valve with high cost which is not easy to block. And the power is 7.5kw. The capacity of the fuel tank is 110 liters. The motor is a Chinese standard brand with good quality and long service life.

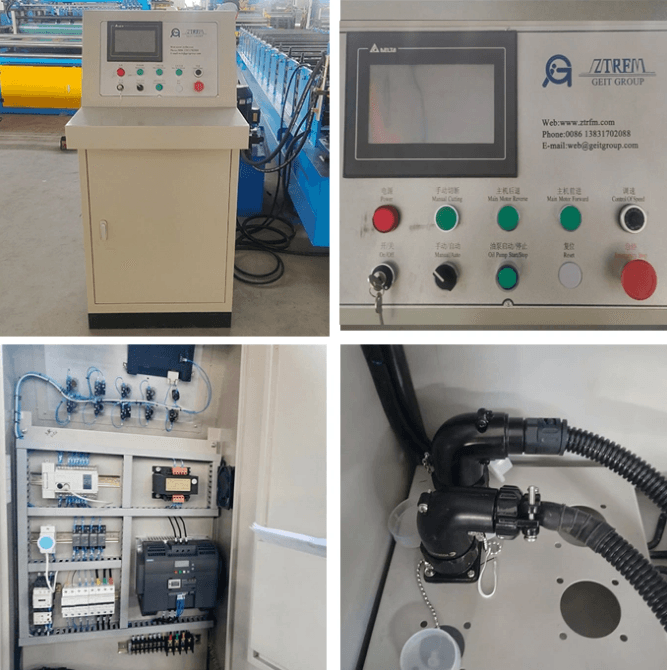

PLC control system

There are touch screen and manual buttons to control the movement of the machine and the length of the sheet.The regular language of the panel is Chinese or English according to your needs.

Equipped with internationally well-known brands such as Delta, Schneider,Siemens.In addition,the electronic contacts in our manual buttons are silver, which has good conductivity, accuracy and long service life.

We adopt Omron counters with accurate counting measurement and good quality. Each wire marked with a number or letter is installed neatly.

The aviation plug used to integrated these wires together is inside a box to protect it.And it is convenient for your use. You can choose to install remote operating system of PLC. So that our engineers will debug it for you remotely when there is a problem with the machine.