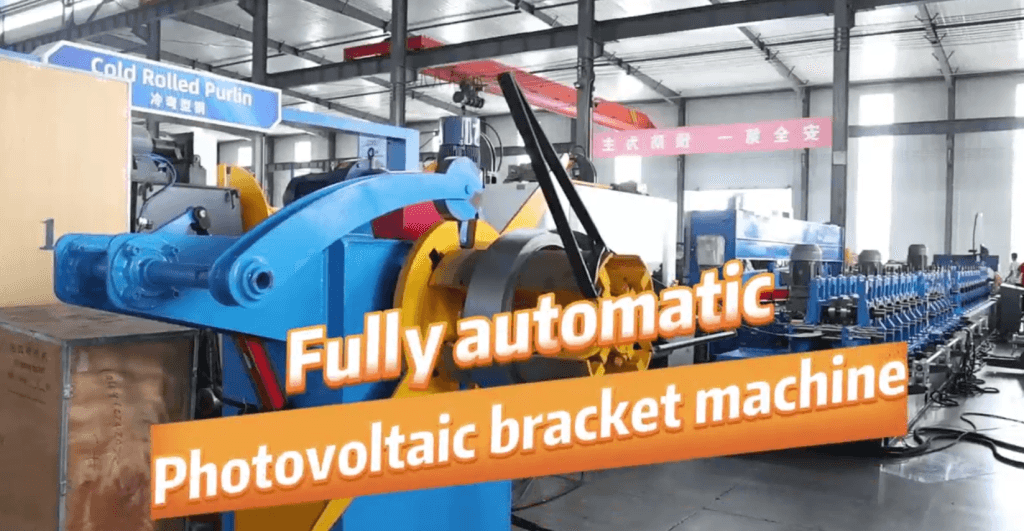

Today, I want to introduce to everyone our solar panel bracket machine, also known as anti-seismic support equipment. This device has many differences from other devices on the market.

First of all, we should more accurately call it a production line. It is fully automated from uncoiling, feeding, forming, to punching, scaling cutting, and automatic coding. Only one employee is required to assist in the operation.

Let’s start with the introduction of the uncoiling machine. The uncoiling machine is equipped with a driving motor, which adopts hydraulic internal tension and active transmission. We also installed a pressure wall to prevent the material from becoming loose due to excessive speed during operation. In addition, we have a pressure arm and four supporting wheels to ensure that the inner ring of the material will not be damaged and maintain a circular shape. The design of the side reversing stop is also to assist the smooth operation of the material during operation.

The design of the feeding part must ensure the smooth operation of the material and the accurate positioning of the material without deviation, fluctuation or jump. We use an upper and lower rolling horizontal side rolling design to ensure accurate material positioning and no movement. The hardness of the roller is above 58 degrees, wear-resistant, ensuring that the material enters the equipment continuously, smoothly and quickly for a long time, and at the same time, the positioning is accurate, and it does not wear itself and does not consume.

Our machine adopts gear phase transmission, because customers require protection of the surface of the new city, so we designed the equipment to be longer and use three transmission motors. For photovoltaic supports and earthquake-resistant supports, we can complete the manufacturing of various shapes through one equipment and automatically adjust the height through the opening and closing mode.

A linear guide rail is installed under the equipment base, and a bi-directional adjustable 4V motor is used to select the model through the control cabinet, which is simple and convenient. This equipment is designed for Russian customers, and we also add our own logo to the equipment of foreign customers. This equipment can be used for both photovoltaic supports and earthquake-resistant supports. Photovoltaic supports are used for the installation of photovoltaic panels, and earthquake-resistant supports are used for supports of large ventilation pipes in shopping malls, garages, etc. to prevent loosening caused by earthquakes or other vibrations.We installed anti-slip gauges on the machine to ensure the operation speed and forming effect of the equipment. The front opening and closing part of the equipment has completed the adjustment of the facade height, and through the combination of the vertical rail and the horizontal rail, it is ensured that the material does not rebound, the indentation position is fixed, and the material shape is maintained correctly and beautifully. We also use a 45-degree inclined cone rail to reduce the inner edge angle, making the material shape more beautiful.

Although this technology seems simple on the surface, it requires many skills to truly apply it. This is also a technology for which we have obtained an invention patent.