The roofing sheet machine of GEIT Group is composed of six parts: Decoiler System,Main Roll Forming System , Hydraulic Station, Electric Control System, Shearing Mechanism, Products receiving table. Guide Feeding Device is a part that is after decoiler system and before main rolling forming system. I will introduce it to you today.

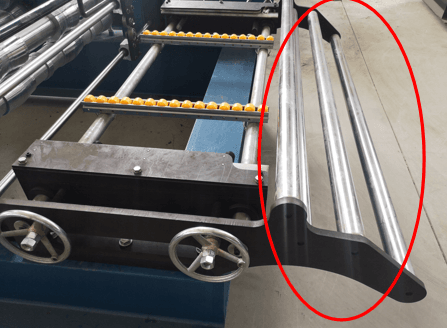

“3 supports&1 pressure” on our machine is composed of three stainless steels which are below the steel plate to support steel coils and one stainless steel which can prevent steel coils from curling. The design make the steel enter main roll forming system according to the established position.

Guide Feeding Device is equipped with two or three rubber rollers which prevent direct contact between the steel and machine and protect the steel.

There is a hollow design in the steel plate of Guide Feeding Device. The design can reduce the weight of the machine. At the same time, the strength of the steel plate to undertake steels is unchanged.

What we can see is a rolling roller designed in the Guide Feeding Device. There are two nylon liners on the upper and lower sides, and its purpose is to ensure the steel is not scratched. The nylon board above has a little missing which can make it easy to observe the feeding situation. Besides, the screws embedded in the nylon board can also reduce friction on the surface of steels.

Our guide feeding device with four hand wheels can adjust the width and the position of the feeding material. This design that makes the feeding material more accurate is an advantage of our machines.

Plate shearing device and Film covering device are not necessary structures of roofing sheet machine. Customers can freely choose whether to install them according to requirements.

The above contents are the introduction to our Guide feeding device. Please contact with us at any time if you have any questions.