Introducing the High-Speed Roofing Machine for Trapezoidal Tiles. Tailored for swift production of trapezoidal roof tiles, this machine is engineered to boost production efficiency while guaranteeing product excellence. Through the integration of cutting-edge technology and superior materials, it accomplishes high-speed production while sustaining stability throughout the manufacturing cycle. Notable characteristics encompass swift and efficient operation, dependable performance, and accurate material handling, positioning it as a superior option for manufacturing trapezoidal roof tiles.

Profile drawing for reference:

Technical Specifications of the High-Speed Trapezoidal Roofing Machine:

Material Formed: PPGI, GI, AI

Thickness Range: 0.3mm to 1.0mm

Width: 1000mm/1250mm (customizable)

Roller Station Configuration: 26 rows (as per your requirements)

Shaft Diameter: 80mm solid shaft

Roller Material: 45# steel with a hard chrome plated surface

Machine Body Construction: Made of 350 H steel

Motor Power Rating: 5.5KW

Voltage and Frequency: 380V, 50Hz, 3-Phase (customizable)

Control System: PLC-based

Forming Speed: 0 to 60 meters per minute

Cutting Method: Hydraulic cutting

Hydraulic Power Rating: 7.5KW

Cutting Blade Material: CR12MOV, scratch-resistant and deformation-free

Cutting Accuracy: +/-1mm tolerance

The Benefits of the High-Speed Trapezoidal Roll Forming Machine:

We possess the expertise to produce various types of roof sheet machines tailored to client specifications. This specific machine stands out for its high-speed operation, enhanced stability facilitated by gearbox transmission, and a sturdy cast iron framework.

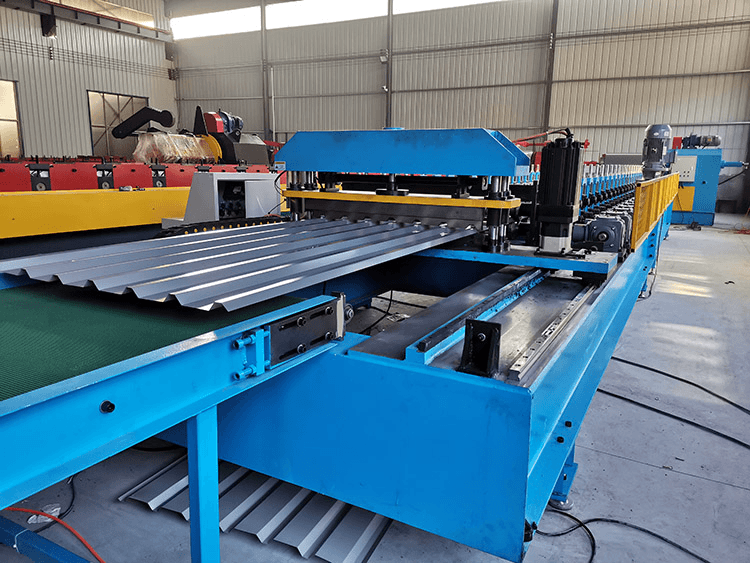

Product Exhibition:

Hydraulic Decoiler

Equipped with automated features for independent operation.

It automatically adjusts to accommodate coils of various diameters.

Features a pneumatic braking system for superior control and safety measures.

Includes a press arm to secure coils and prevent any loosening.

Roll Forming Device

Roller Station: 26 rows (customizable as per your requirements)

Shaft Diameter: 80mm solid shaft

Roller Material: 45# steel with a hard chrome plated surface

Machine Body Construction: Made of 400H steel

Drive Chain: 1.2 inches (customizable as per your requirements)

Hydraulic Cutting Device

We employ a pillar-based cutting system structure, ensuring stable cutting operations. The hydraulic oil pump station powers the cutting system, enabling efficient and dependable cutting processes.

PLC Control System

PLC Brand: Delta (Taiwan)

Frequency Converter Brand: Delta (Taiwan)

Encoder: Omron

Function: Automatically controls length, quantity, and batch production.