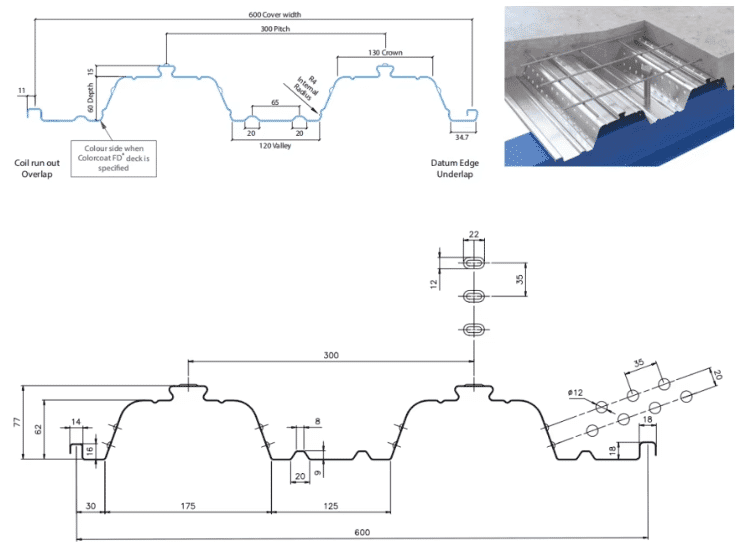

Our Composite Metal Floor Decking Roll Forming Machine is engineered for high-efficiency, fully automated batch production of metal decking sheets. The machine is capable of forming a combined trapezoidal and re-entrant 80mm composite profile, offering excellent long span capability and versatility. This profile allows for easy service attachments, combining the benefits of both trapezoidal and re-entrant design for superior spanning ability.

Key Features Of Floor Decking Roll Forming Machine:

- Customizable Design: The machine accommodates various decking profiles with different heights and embossing types, tailored to meet customer specifications based on input coil width and requirements.

- Smooth Surface Frame: Designed to maintain a smooth surface and prevent marks during the stamping process, ensuring quality in every production cycle.

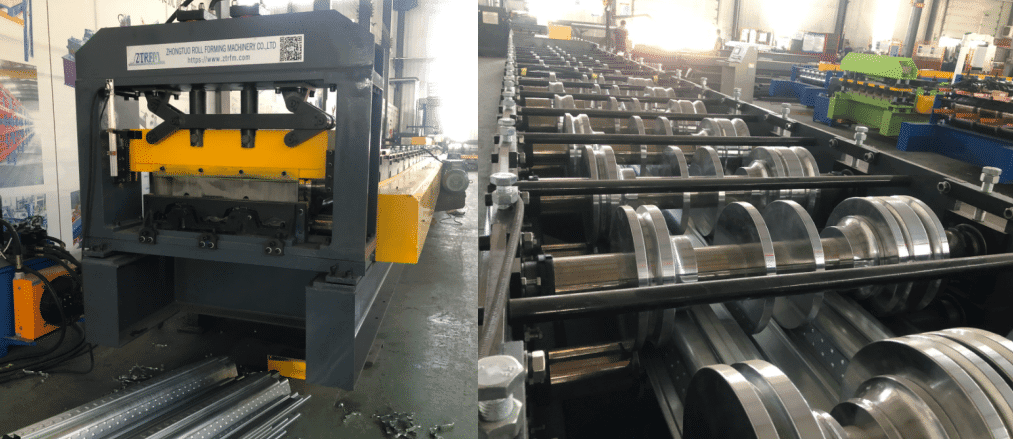

Specifications:

- Frame Dimensions: 25,000 x 1,650 x 1,500 mm

- Weight of Main Part: 15,300 kg

- Voltage: Customizable to meet specific power requirements

- Roller Fixer: 28mm thick middle plate for optimal stability

- Frame Material: 400H steel welded frame for durability

- Drive System: Dual chain drive with adjustable tension for seamless operation

- Roller Material: GCr15 steel with hard chromium plating for extended durability

- Shaft Material: 45# steel, hardness adjustable for precise performance

- Shaft Diameter: φ90mm, with embossing rollers at approximately 120mm

- Number of Rollers: 36 rollers for shaping versatility

- Main Power: 15*2 kW for efficient operation

Shearing Mechanism:

- Precision and Stability: The hydraulic-powered cutting system ensures high precision, stability, and cutting speed.

- Automatic Cutting Control: PLC-controlled automatic cutting system for customized product dimensions and efficient production.

- Hydraulic Drive: Features automatic location positioning to achieve precise cuts according to target dimensions.

- Blade Material: High-quality Cr12 quenched steel for sharpness and durability

- Hydraulic Power Supply: Ensures reliable performance for continuous production.

Optional Features:

- Pre-shearing Function: The pre-shearing option allows the machine to cut at any desired length, reducing coil wastage and improving material utilization.

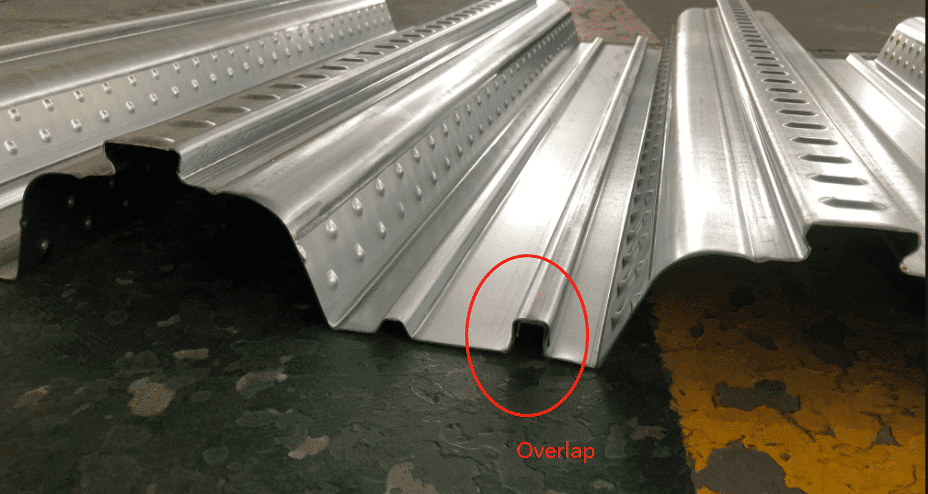

Note on Overlap Effect:

The metal decking profile features a dovetail-shaped design, which requires the use of numerous side rollers to form accurately. This sophisticated shaping process contributes to the profile’s strength and versatility, ensuring maximum performance even under demanding conditions.