Cangzhou Zhongtuo Roll Forming Equipment Co., Ltd. specializes in manufacturing high-tech roll forming machines, including the advanced wall panel cladding machine. This roll forming machine is designed with a high level of automation, making the production process smooth and highly efficient. Equipped with a state-of-the-art servo tracking cutting system and an automatic roller punching function, it ensures seamless operation without any interruptions or malfunctions. The use of a frame-type structure enhances the stability and precision of the machine, making it an ideal choice for manufacturers looking for reliability and durability. The entire process, from rolling to cutting, runs flawlessly, significantly reducing maintenance costs and downtime while improving overall production efficiency.

Energy Efficiency & Sustainability

One of the standout features of this wall panel cladding machine is its exceptional energy efficiency. Despite its high productivity, it consumes minimal power, helping businesses save on electricity costs while aligning with eco-friendly and sustainable manufacturing practices. For companies focused on long-term sustainability, this machine is a perfect investment, ensuring reduced carbon footprints while maintaining superior performance.

High-Quality Metal Wall Panels

Metal wall panels, also known as corrugated panels or Great Wall panels, are a modern cladding solution that offers both aesthetic appeal and functional benefits. Made from premium metal sheets and formed through CNC bending technology, these panels are coated with fluorocarbon paint for enhanced durability. The design of the panels mimics the appearance of the Great Wall, providing a unique visual effect that is increasingly popular in architectural projects.

Advantages of Metal Wall Panels:

- Lightweight & High Strength: Easy to install without compromising structural integrity.

- Waterproof & Corrosion-Resistant: Suitable for both interior and exterior applications.

- Fireproof & Stain-Resistant: Ensuring long-lasting performance with minimal maintenance.

- Cost-Effective & Durable: Reducing long-term maintenance costs and extending lifespan.

These panels are widely used in various architectural applications, including exterior facades, edge wrapping, lobby column decorations, corridors, and interior ceiling designs. With the growing popularity of modern design concepts, Great Wall panels have become a trending choice in the decoration industry.

Superior Manufacturing Process with Zhongtuo’s Roll Forming Machine

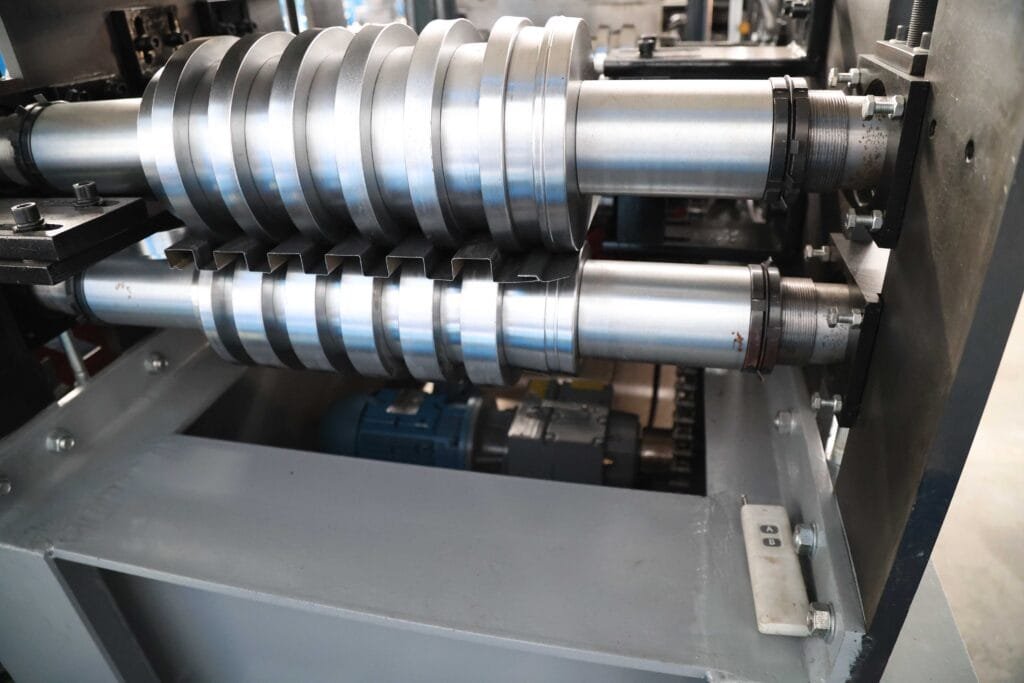

Zhongtuo’s wall panel cladding machine is designed to produce high-quality panels with precision. The machine ensures that each panel maintains a smooth and flat surface, with a strong three-dimensional appearance. From the feeding rollers to the guide rollers and manual cutting tools, every component plays a crucial role in preserving the quality of the sheet surface. The machine’s design continuously evolves to solve real-world manufacturing challenges, enhancing equipment configuration to improve efficiency.

A key innovation in this roll forming machine is its edge-forming system. The side rollers precisely shape the edges to ensure straightness and smoothness of the final product. Another major improvement is the positioning of the cutting mechanism. If the cutting blade is placed at the end of the process, the edges may become flattened, complicating installation. Zhongtuo’s machine addresses this by cutting the panels first and then using two parallel roller sets and two vertical roller sets to shape the final product. This eliminates the need for manual post-processing, ensuring perfect panel formation with every cycle.

Smart Automation & Industry 4.0 Integration

To maximize space efficiency, the hydraulic station and control cabinet are strategically placed above the machine. This setup not only optimizes workspace usage but also enhances accessibility. The integration of Siemens components further elevates the machine’s performance by enabling remote operation, real-time data collection, and intelligent diagnostics. The incorporation of Industry 4.0 technology allows users to monitor the equipment’s status anytime, receive early warnings, and automatically halt operations in case of malfunctions. This advanced level of automation transforms traditional manufacturing into a highly efficient, intelligent, and innovative production process.

The Future of Roll Forming Technology

Zhongtuo is committed to pushing the boundaries of roll forming technology by blending mechanical excellence with digital intelligence. By leveraging cutting-edge control systems and automated workflows, this wall panel cladding machine ensures precision, efficiency, and sustainability in production. Whether for large-scale industrial applications or customized architectural designs, Zhongtuo’s roll forming solutions offer unmatched quality and reliability.

For businesses looking to enhance their manufacturing capabilities, investing in a Zhongtuo roll forming machine is a step toward a smarter, more efficient, and future-ready production environment.