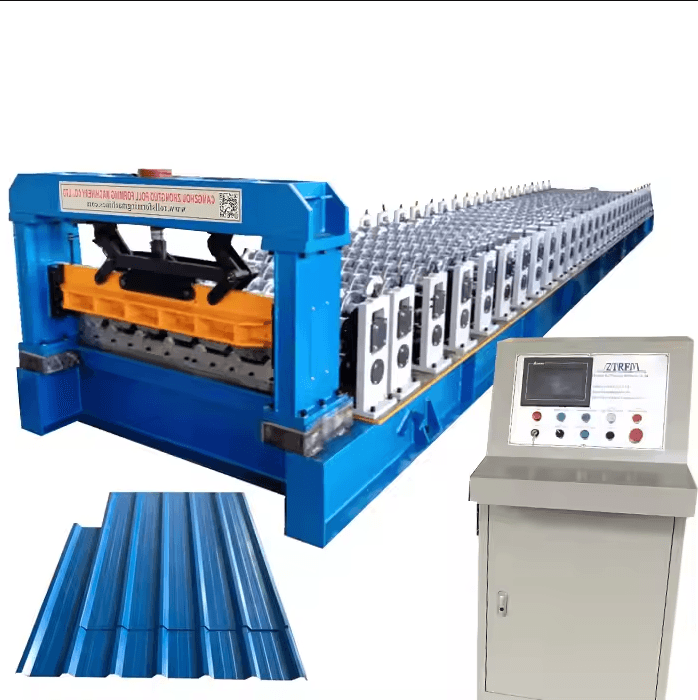

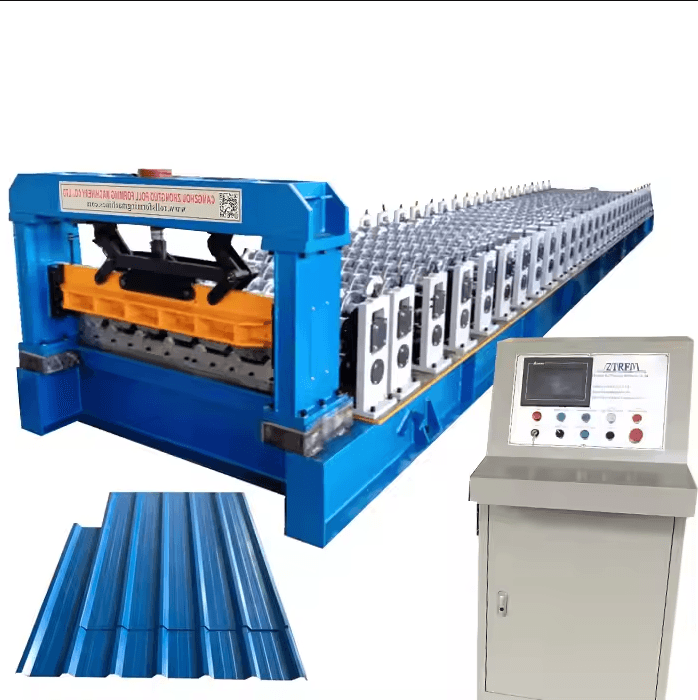

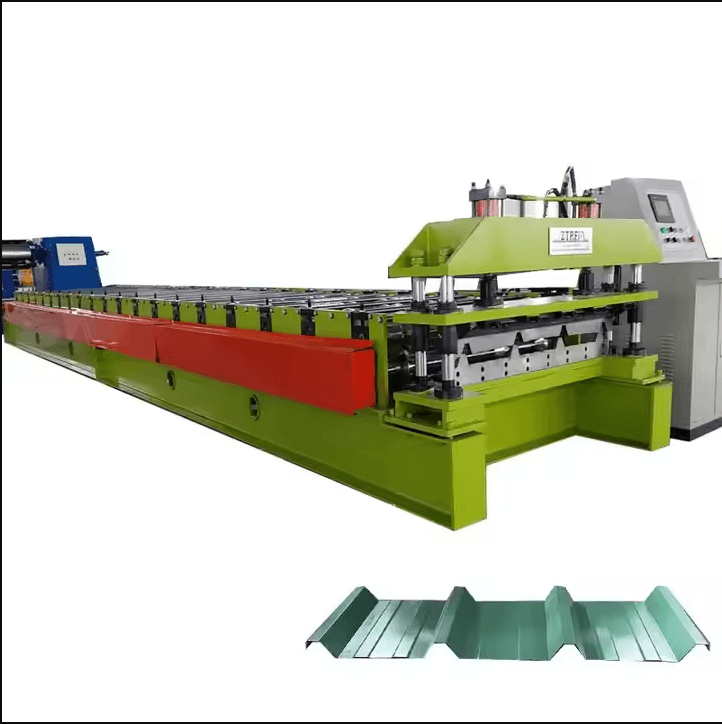

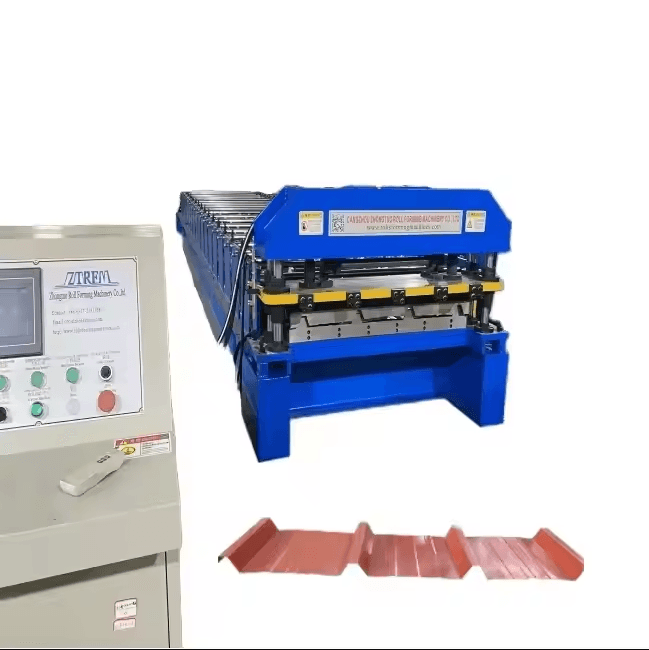

Roofing Sheet Roll Forming Machine

We offer a wide range of roofing solutions through our Roofing Sheet Making Machines, which provide an economical and durable option for metal roofs. These machines are ideal for producing various types of metal roofing sheets, which are lightweight compared to concrete or clay tiles, and more durable than asphalt shingles. Additionally, these roofing materials are easier to handle than traditional metal roof tiles. ZTRFM Roofing Sheet Making Machine is a reliable and affordable roofing solution, available in various styles and designs to meet diverse needs.

Our roll forming machines can produce roofing sheets that mimic the appearance of materials such as wood shakes, asphalt shingles, and slate. However, the metallic finish may not always replicate the authenticity of these materials. Our offerings cater to architects and builders seeking unique designs for roofing and facades, allowing flexibility for different architectural needs.

We provide a variety of metal roofing panel types, including

- R Panel Profile

- U Panel Profile

- TUFF-RIB Panel Profile

- Box Rib Panel Profile

- AG Metal Panel Profile

- Corrugated Panel Profile

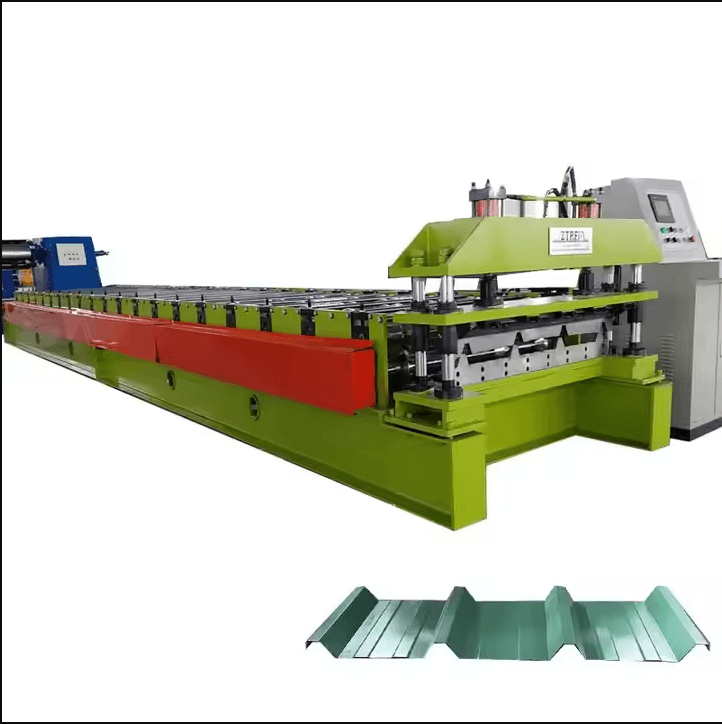

- Standing Seam Metal Roof

- Batten Style Panel Profile

- Glazed Tile Profile

DO YOU WANT TO KNOW MORE ABOUT ROOFING SHEET TYPES?

These profiles can be used for a variety of applications such as commercial, industrial, and residential buildings. In addition, we offer machines capable of producing these sheets to meet specific project requirements.

ZTRFM specializes in high-quality galvanized roofing sheet making machines, which are perfect for use in both industrial and agricultural applications. These sheets are particularly suitable for cladding walls and providing additional security in settings like barns, farms, and storage facilities. Our machines also support the production of several popular roofing materials, including

- Standing Seam Metal Roofs

- Steel Roofing Sheet

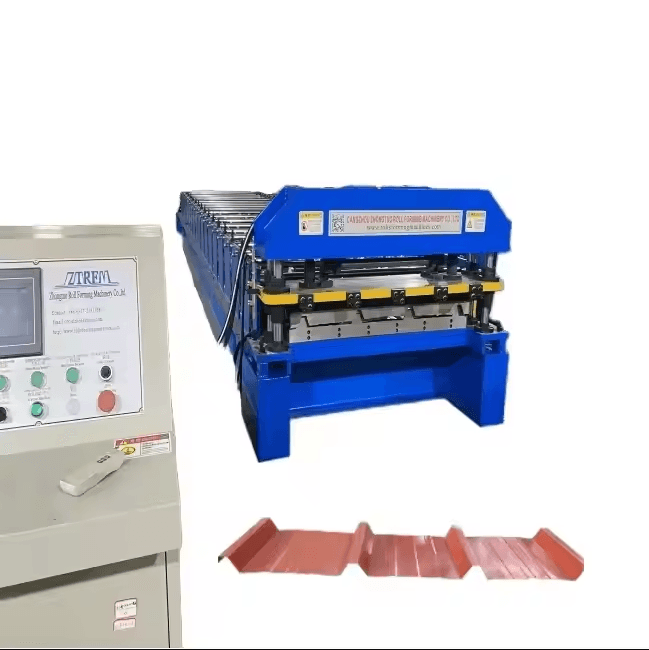

- IBR Roofing Sheet

- Trapezoidal Roofing

- Wall Cladding Sheet

Our Trapezoidal Sheet Making Machines are especially popular for their corrosion resistance and aesthetic appeal, used extensively in the construction industry worldwide. These sheets are perfect for steel structure buildings and containment systems, offering an efficient solution for roof and wall cladding.

We also manufacture Stainless Steel Panel Roll Forming Machines, which are highly regarded for producing roof and wall panels in stainless steel. These machines can be customized to meet specific customer needs, including different sheet thicknesses and profiles.

In addition, our IBR Sheet Roll Forming Machines are designed for use in commercial, industrial, and residential roofing applications. The IBR profile is particularly popular in South Africa and is available in various materials, including steel and aluminum. Our machines can produce both IBR 686 and IBR 890 profiles, with the 686 profile being the most widely used.

ZTRFM is a leading manufacturer in China, specializing in roll forming machines for roof and wall cladding. We are committed to providing high-quality machines to help you produce durable, reliable roofing solutions.

Roof sheet tiles are produced using specialized roofing sheet making machines, which are essential for crafting various types of metal roofing materials such as tiles for residential roofs, IBR sheets, and color-coated sheets used in the market. If you’re interested in acquiring roofing machines, consider ZTRFM, a company with over 10 years of experience in manufacturing roof tile production machines. They produce more than 300 different profiles for various needs. Depending on the customer’s location and requirements, ZTRFM provides both standard-speed and high-speed metal roof-forming machines. These machines are equipped with over 600 rollers and between 30-60 shafts, ensuring high quality and efficiency.

When selecting a factory to produce metal roofing sheet making machines, it’s important to evaluate the workshop capacity and the company’s experience in roll forming. This ensures you’ll receive long-lasting and reliable IBR sheet roll forming machines.

Best Materials for Metal Roof Tiles:

- Iron: Known for being cost-effective, iron is commonly used in roofing tiles. A popular choice is corrugated galvanized iron, though iron panels may also be coated with steel for enhanced durability.

- Stainless Steel: This material is widely used for metal roofing due to its affordability and strength. However, it is prone to corrosion and is usually coated with special paint to protect against this. Stainless steel roofing comes in a range of colors, making it a versatile choice for homes.

- Galvanized Steel:This type of steel is coated with zinc to enhance its corrosion resistance. Similarly, Galvanized Steel is coated with aluminum, offering increased durability, strength, and resistance to corrosion.

High-Speed Roof Tile Machines:

ZTRFM offers a variety of roof tile forming machines that can operate at high speeds to produce PPGI and GI sheets. These machines are known for their high-quality output, precise sheet lengths, and reliable performance. They are equipped with servo motors to minimize tolerance and maximize speed. ZTRFM can also customize machines to match specific designs and cutting shapes based on customer requirements.

The company’s stamping molds are meticulously designed by professional engineers and undergo a multi-step process including wire cutting, hardening, surface treatment, and heat treatment to ensure accuracy and high-quality results. The glazed roof tile machines feature between 15 to 20 tooling stands to ensure smooth and consistent forming.

If you have questions regarding roofing sheet making machines, you can find detailed answers to common queries on our YouTube channel, where we provide comprehensive insights about our products and services.