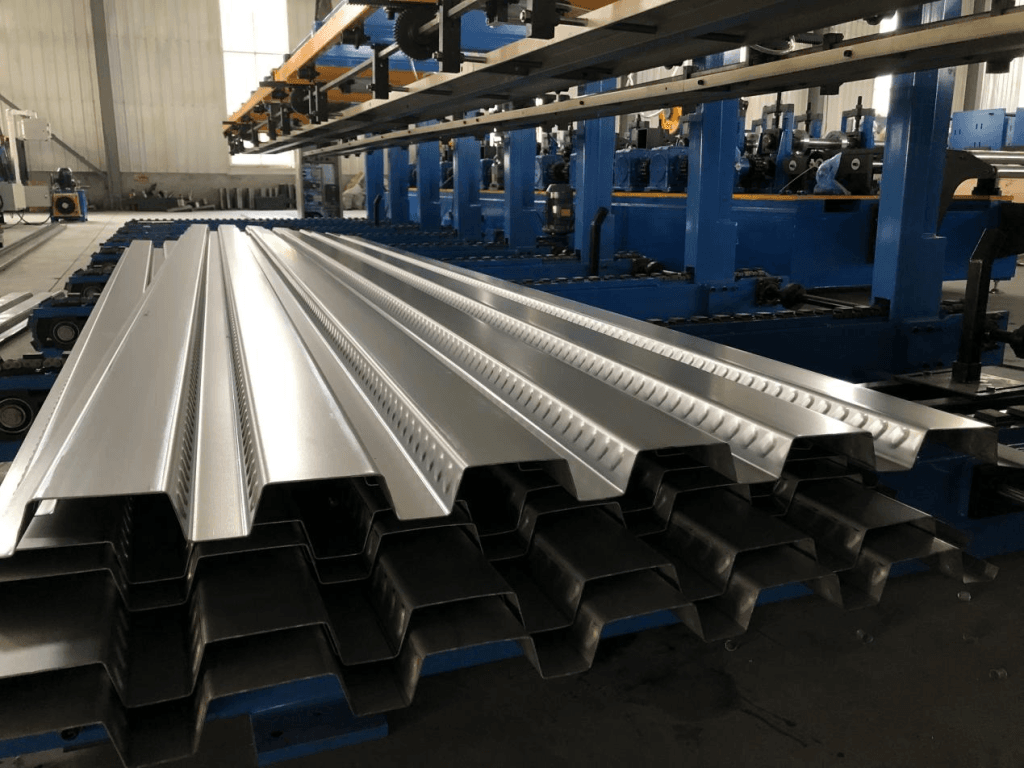

The B-Deck Roll Forming Machine is designed to manufacture B-Deck metal decking, a widely used structural decking solution. B-Deck panels are known for their lightweight, strong, economical, and easy-to-install features, making them ideal for construction projects that require both strength and sustainability. B-Deck is commonly used for applications such as flooring, siding, and roofing.

Types of B-Deck:

- B Roof Deck: A composite metal floor deck panel designed to have concrete poured over it.

- B Floor Deck: Primarily used for flooring purposes, offering excellent durability and load-bearing capacity.

Both types of B-Deck share identical dimensions, including:

- 36” coverage

- 1.5” rib height

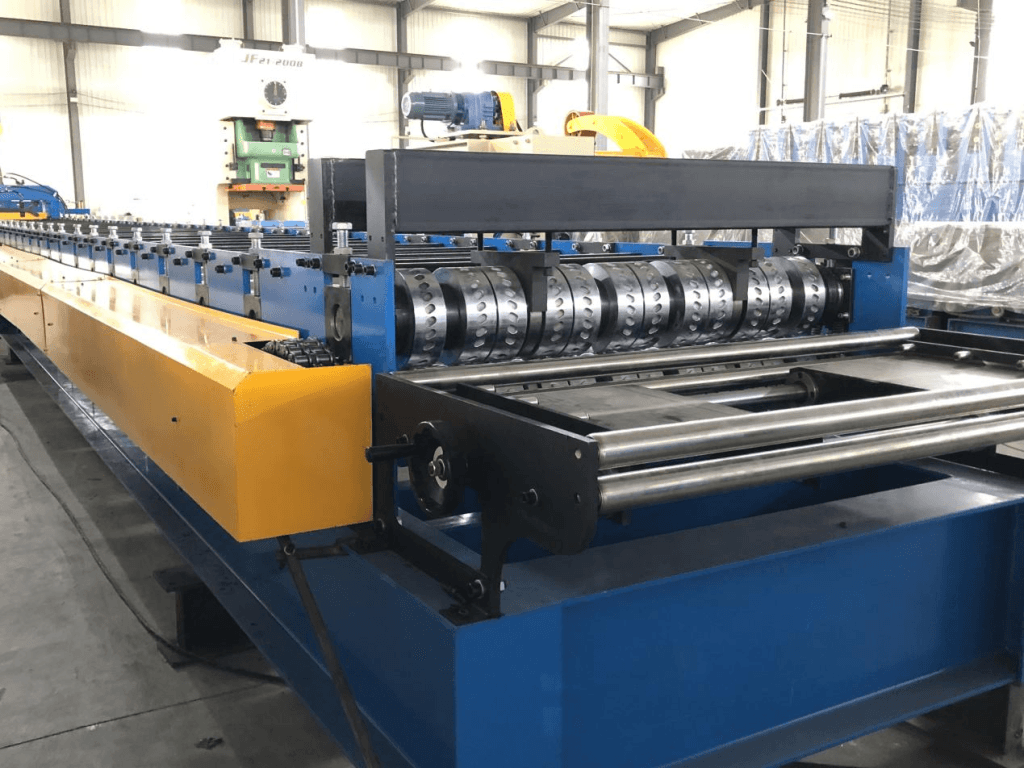

B-deck Roll Forming Machine Features and Components

Feeding Device

- 2 Rollers: Designed to reduce friction during material feeding and prevent surface scratches.

- Stainless Steel Rollers: Ensure smooth material flow and protect the material surface from damage.

- Adjustable Feeding Width: The hand wheel allows for precise control of feeding width, enhancing feeding accuracy.

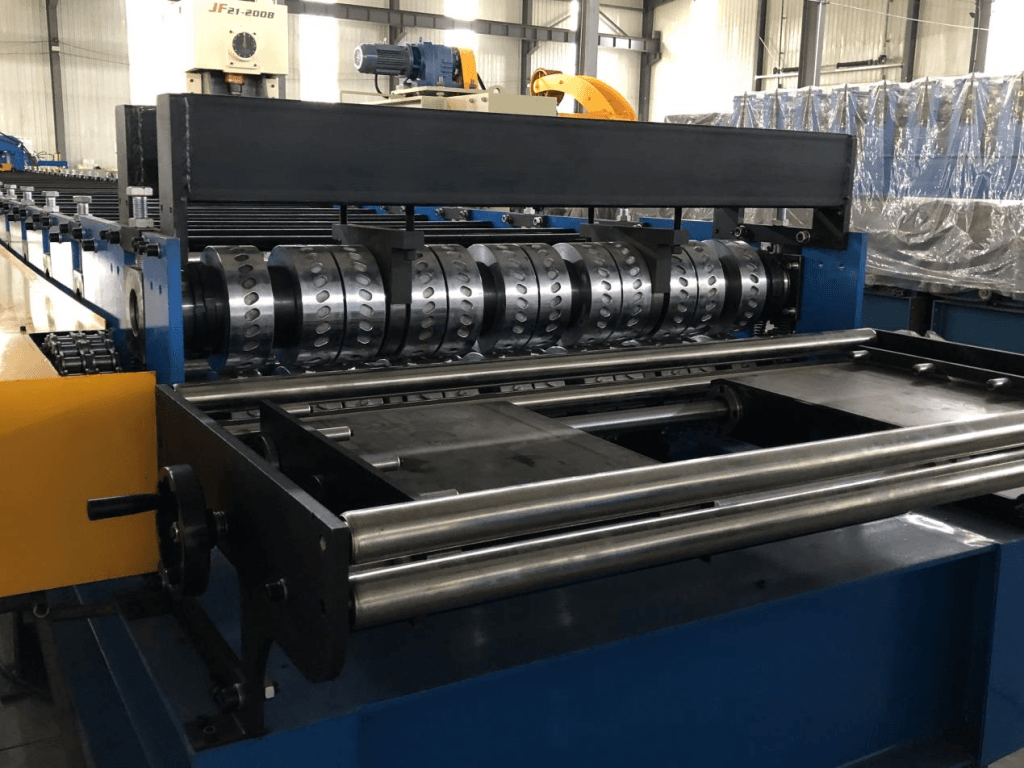

Roll Forming Device

- High-Quality Rollers: Made from GCr15 steel with HRC 58-60 hardness for enhanced durability and long service life.

- Stable Roller Installation: Each roller is numbered and equipped with keynotes, ensuring stability on the shaft.

- Heavy-Duty Frame: The machine features a robust frame made from thick materials, ensuring exceptional stability during operation. Additionally, diagonal bracing is added for extra stability.

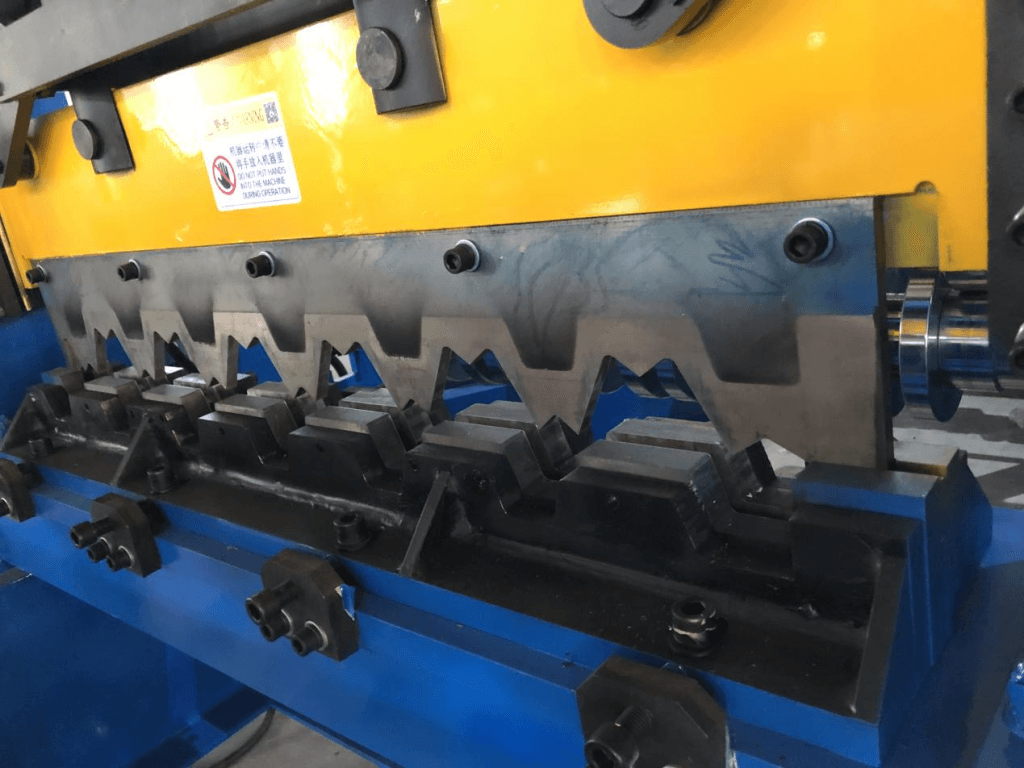

Automatic Shearing System

- Durable Cutter: Constructed from GB-Cr12 steel and heat-treated for long-lasting performance.

- Precise Cutting: Tolerance within ±2mm per 10 meters, ensuring accurate and consistent cuts.

- Low Noise and Safe Operation: The cutting system operates with minimal noise, providing a safer and quieter working environment.

PLC Control System

- Brand: Delta PLC (Taiwan), with an intuitive touch screen interface.

- Encoder: Omron encoder for precise control and monitoring.

- Electrical Components: Equipped with Schneider electrical components for reliable performance.

- Bilingual Operation: The system supports both English and Chinese languages (or custom options as required). Users can easily set order lengths, quantities, and other parameters, making the machine highly user-friendly.

- Easy Installation: The system features aviation plugs for straightforward machine installation upon arrival.

Hydraulic Station

- Motor: 5.5 kW for powerful hydraulic operation.

- Hydraulic Oil: Uses 46# hydraulic oil for optimal performance.

- Main Components: Includes a hydraulic tank, oil pump, two hydraulic pipes, and an electromagnetic valve for efficient and stable operation.