Box profile roofing sheets, produced using the latest metal box profile roofing sheet rolling machines, are becoming one of the most popular choices in the market. These modern roofing sheets offer a sleek alternative to the traditional corrugated style, all at a highly competitive price of approximately 6.5 USD per meter.

What Are Box Profile Roofing Sheets?

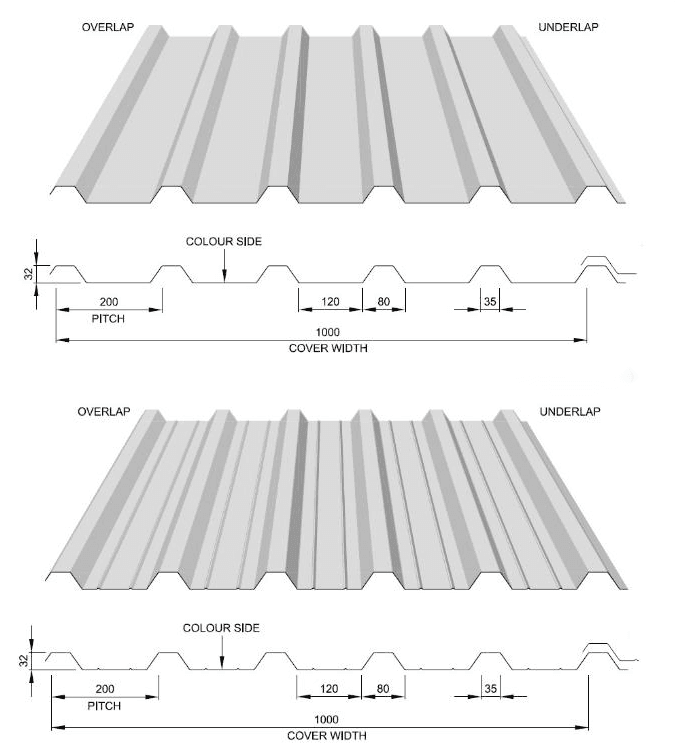

Box profile roofing sheets consist of six profiles and five valleys, with water running through the valleys. Each profile is 32mm deep, spaced at 200mm centers, ensuring strong structural integrity. For added support and stability, two additional ribs are formed in every valley of the sheet.

Manufactured from flat-coated steel coils, box profile roofing sheets are processed using a roll forming machine. The flexibility of this machine allows for customization in sheet lengths and thicknesses, catering to diverse roofing requirements.

The box profile roofing sheets are a modern alternative to the traditional corrugated metal roofing. Their effective cover width is 1000mm, and they feature a capillary groove along one edge, eliminating the need for sealing strips while preventing water ingress.

Whether you are constructing a commercial building or a residential roof, box profile roofing sheets provide durability, easy installation, and superior water resistance, making them an ideal roofing solution.

Roll Forming Machine

Coil Material: GI, PPGI, SS, HR, CR. 235-550MPA

Thickness range: 0.2-0.8mm

Line Speed : 15-20m/min

Main motor power: 7.5KW

Machine Voltage, Frequency, Phase:440 V, 50 Hz, 3Phase

Roll station: 20 stations

Roller material:ASTM 1045 chrome plated surface with hardness 58-62 degree ,CNC,

Shaft diameter: ¢76mm material: ASTM1045 with quenching and tempering

Transmission: by chain

Machine base frame adopt H beam welding steel

Machine chromed pillar as the stands

To avoid accidents,all of drive part adopt protect cove