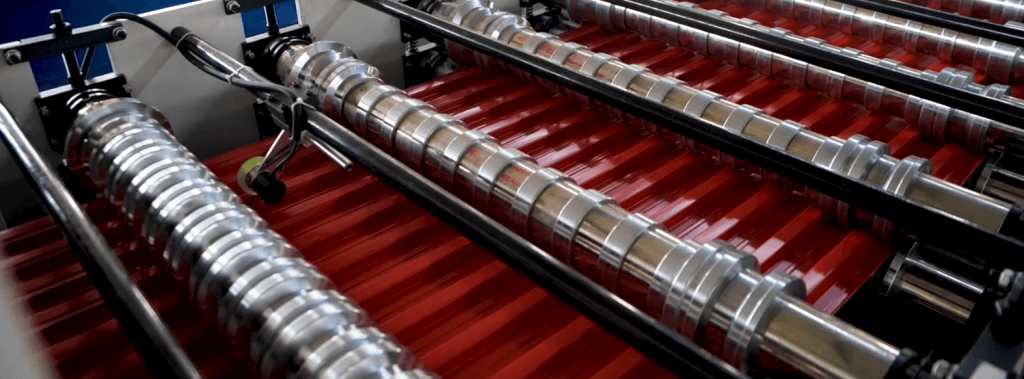

The Australian-style roller shutter door forming machine adopts an advanced split-body forming technology, which ensures that each wave peak in the forming process is not restricted by tensile forces, thereby guaranteeing the uniformity and flatness of the wave peak heights. During the forming process, the number of wave peaks gradually increases, and each step of the forming process exhibits a uniform and neat appearance, thanks to the precise control of the split-body forming mode.

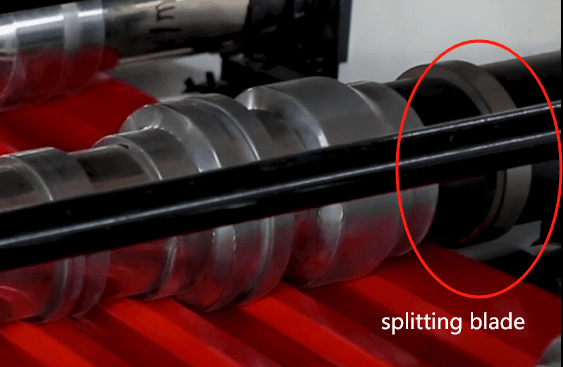

Compared to ordinary roofing sheet making machines, the Australian-style roller shutter door forming machine features an additional unique device. This device plays a crucial role as it directly relates to the precise overlapping of the two sides of the Australian-style roller shutter door. Since the Australian-style roller shutter door has strict requirements for the width of the material, being too wide will prevent smooth rolling, and being too narrow will affect the overlapping effect, so the width of the material must be precise.

During the material feeding process, to avoid waste caused by inaccurate material width, we cleverly installed a splitting blade on the shaft. When the material width exceeds the set range, the splitting blade can quickly and accurately cut off the excess part, ensuring that each piece of material meets production requirements.

To further enhance production efficiency and automation levels, we have also added a driven waste collection device. This device can automatically collect the cut-off waste without manual intervention, thereby ensuring the continuous and stable operation of the equipment. During the production process, workers only need to monitor the status of the waste collection device and promptly unload the waste when it is full.

In summary, by adopting split-body forming technology and a unique waste disposal device, the Australian-style roller shutter door forming machine not only ensures the stability and consistency of product quality but also significantly improves production efficiency and automation levels, providing strong technical support for the production of Australian-style roller shutter doors.