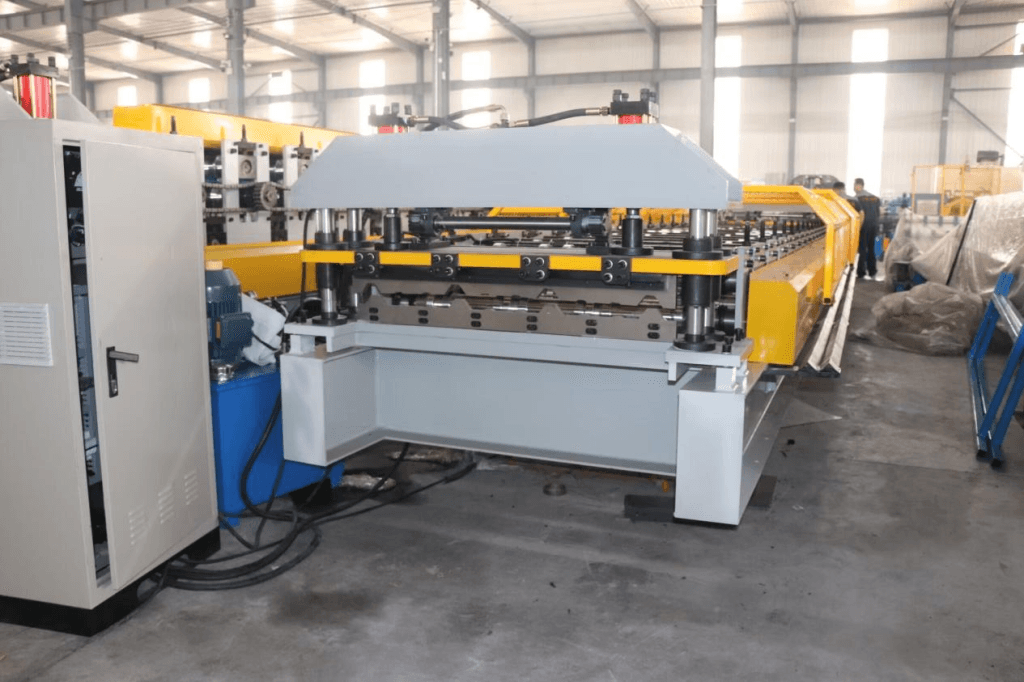

A PBR (Purlin Bearing Rib) roof panel roll forming machine is an industrial tool utilized within the construction and manufacturing sectors. It is engineered to automate the formation of PBR roof panels, a type of metal roofing commonly employed in the construction of diverse structures such as warehouses, industrial sites, agricultural buildings, and beyond.

PBR panel metal roofs represent a durable and aesthetically pleasing option for metal roofing. Their ease of installation reduces labor costs, time, and disposal expenses. These R-panel roofs come in a variety of colors and are highly favored for both residential and commercial roofing systems.

Here is one drawing profile and finished product:

Production technology process:

Feeding → Leveling → Forming → hydraulic Cutting after forming → Output

The pricing of ZTRFM’s roll forming machines is slightly higher compared to other suppliers. Allow me to elucidate the distinctions of our machines:

ZTRFM’s machine design is a unified unit, where the control box and hydraulic station are integrated under the machine frame. Upon receiving the machine, there is no need for assembly or complex cable connections; only a single main cable needs to be connected for immediate operation. This design saves both time and space.

Our display screen is a touchscreen, not a text-based one. In the ZTRFM roll forming system, we incorporate hand wheels at the feeding device to adjust the feeding width. These wheels are numbered, making it easy to adjust the left and right sides. We also have rulers on the bedding, allowing you to adjust the profile’s height and width according to the measurements. The screws with numbers facilitate easy adjustment of material thickness. Additionally, protective caps, laminating film devices, and felt are installed to ensure the board is flat, smooth, and scratch-free.

The machine is equipped with a detection switch device that triggers an emergency alarm and stops operation in case of any emergencies.