Stone-coated steel roof tiles, also known as metal roof shingles or stone-coated steel roofing, represent a modern and robust roofing option. Crafted from premium galvanized steel and coated with a layer of stone granules, these tiles offer an attractive appearance reminiscent of traditional clay, slate, or asphalt shingles.

Advantages of Stone-Coated Roof Tiles:

1. Durability: Withstands severe weather conditions, including rain, wind, and hail.

2. Fire Resistance: Non-combustible, ideal for regions prone to wildfires.

3. Energy Efficiency: Reflective qualities reduce heat absorption, leading to energy savings.

4. Low Maintenance: Resistant to cracking, fading, and insect damage.

5. Aesthetics: Available in a wide array of colors and designs.

6. Eco-Friendly: Recyclable and can be installed over existing roofs, reducing waste.

7. Easy Installation: Lightweight, which lowers costs and eases structural demands.

8. Long-Term Value: A stylish and energy-efficient roofing option for the ages.

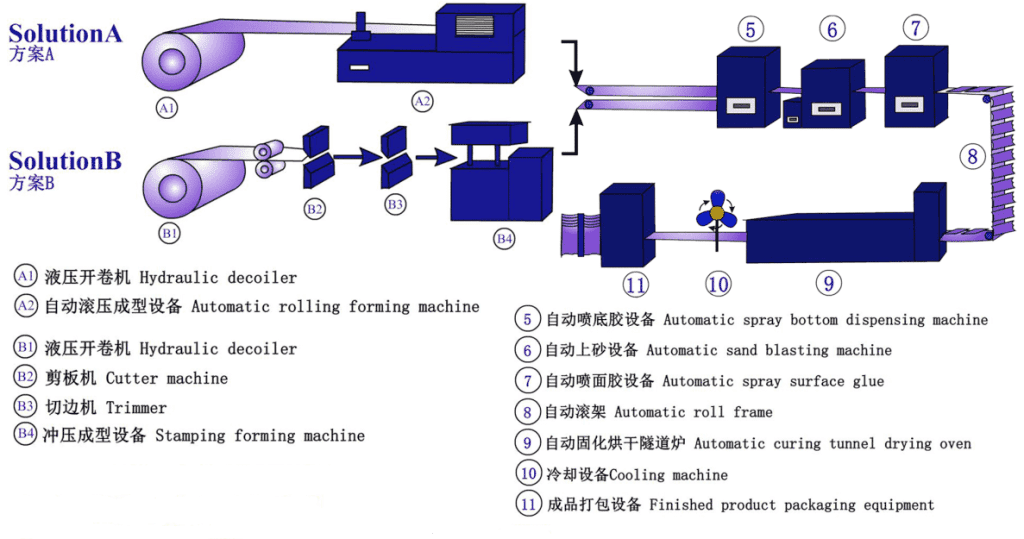

How to Manufacture Stone-Coated Steel Roofing Tiles:

The production of stone-coated steel roofing tiles involves a meticulous process to ensure longevity, weather resistance, and visual appeal. Here’s an overview of the manufacturing steps:

1. Steel Base Preparation

Material Selection: Select high-grade, galvanized steel sheets to serve as the base, with a protective zinc layer to prevent rust and corrosion.

Cutting: Use precision equipment to cut the steel sheets into the required sizes and shapes for the tiles.

2. Adhesive Application

Adhesive Coating: Apply a layer of adhesive to the steel tile surface to bond with the stone granules in the subsequent step.

3. Stone Granule Application

Granule Layering: Scatter stone granules over the adhesive-covered steel tiles, enhancing their appearance and resilience.

Curing: Allow the tiles to cure, ensuring the granules are firmly attached to the adhesive.

4. Acrylic Coating Application

Sealing Coating: Apply an acrylic coating over the stone granules to secure them and provide additional environmental protection.

Drying: Thoroughly dry the acrylic coating, often involving passage through a heated drying tunnel.

5. Quality Control

Inspection: Conduct a thorough check for defects such as missing granules, inconsistent coating, or damage to ensure only top-quality tiles are packaged and distributed.

Packaging: Once they pass inspection, the tiles are prepared for shipping or storage.

6. Optional Steps

Color Coating: Some manufacturers may apply a colored coating over the acrylic for specific color effects.

Customization: Tiles can be tailored to various shapes, sizes, and finishes based on manufacturer and customer preferences.

7. Storage and Handling

Storage: Keep the finished tiles in a dry, sheltered area to prevent damage before installation.

Handling: Handle the tiles carefully during the installation process to prevent damage to the stone granules.

The manufacturing process of stone-coated steel roofing tiles is crafted to yield a product that is resilient, enduring, and capable of withstanding a range of environmental challenges. The end result should be a tile that is simple to install and requires minimal upkeep over its lifetime.