Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

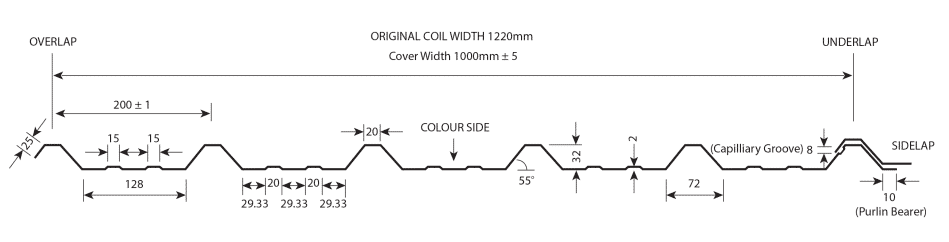

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed can reach about 20M/min, if the capacity is big, we can make the machine speed which can reach 25-30M/min. And some customer they require the thickness of the roofing sheet is 1.2mm. If you want learn more of this kind of machine, choosing our company is your best option.

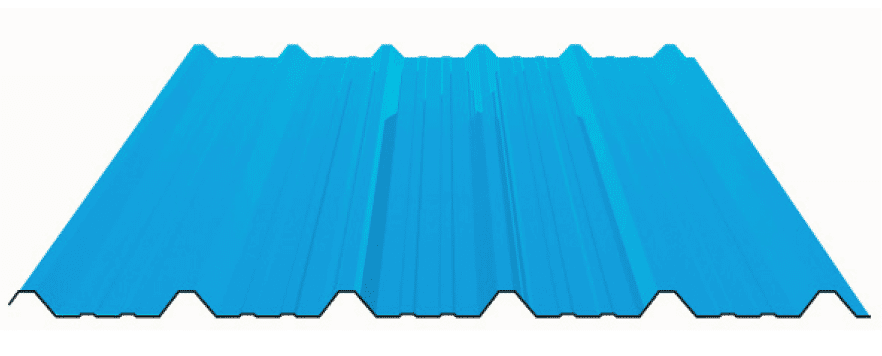

Here is one drawing profile and finished product:

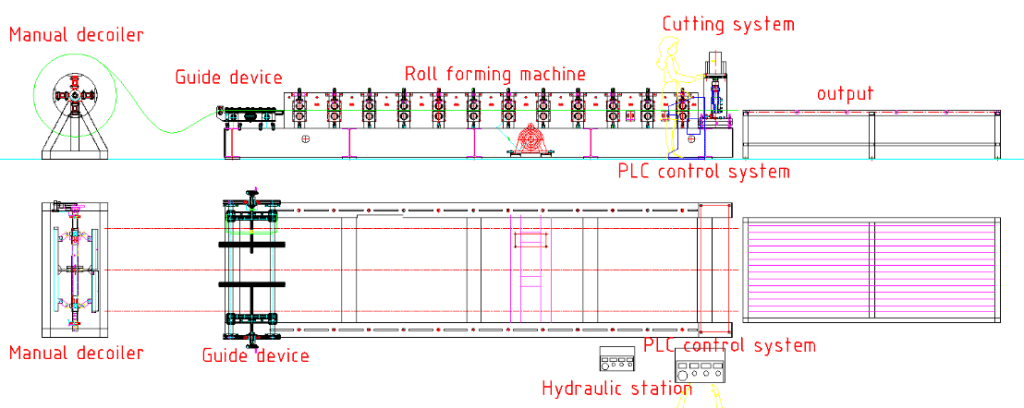

Production technology process:

Feeding → Leveling → Forming → hydraulic Cutting after forming → Output

The price of ZTRFM’s roll forming machines is a little higher than other suppliers’. Let me explain about our machines difference:

ZTRFM’s machine design: it is unit one, which means the control box and the hydraulic station are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. it saves more time and space.

Our display screen is touch screen, not text touch screen.

ZTRFM Processing technology:ZTRFM rollers is through grinding, quenched, chroming,finish machining,polishing,coated with chrome 0.05mm, all rollers are shiny, stronger and avoid rust.etc to make stronger, the roll forming machine is more robust and easier to use. The metal sheet produced by our machine is always flat and perfect profiles., because in the design and during the machining process, we always control the force for the metal sheet, it does not damage the sheet surface and comes out perfect profile.

ZTRFM roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.