The dovetail decking design has gained significant popularity in the Malaysian and Singaporean markets. This advanced composite floor deck system, known as the dovetail floor deck, stands out from other flooring options due to its unique closed design, which lacks any openings. Typically crafted from steel, either hot-rolled or galvanized, this decking system has been experimentally verified to possess superior load-bearing and shear resistance capabilities when compared to open floor deck systems.

The distinctive closed rib shape of the dovetail floor deck ensures that the steel support plate’s ribs are fully encapsulated by concrete, offering protection akin to steel reinforcement in a cast-in-place slab. This maximizes the complementary strengths of steel and concrete. The closed floor deck has seen successful application in stress-reinforced floor systems and is noted for its excellent fire resistance.

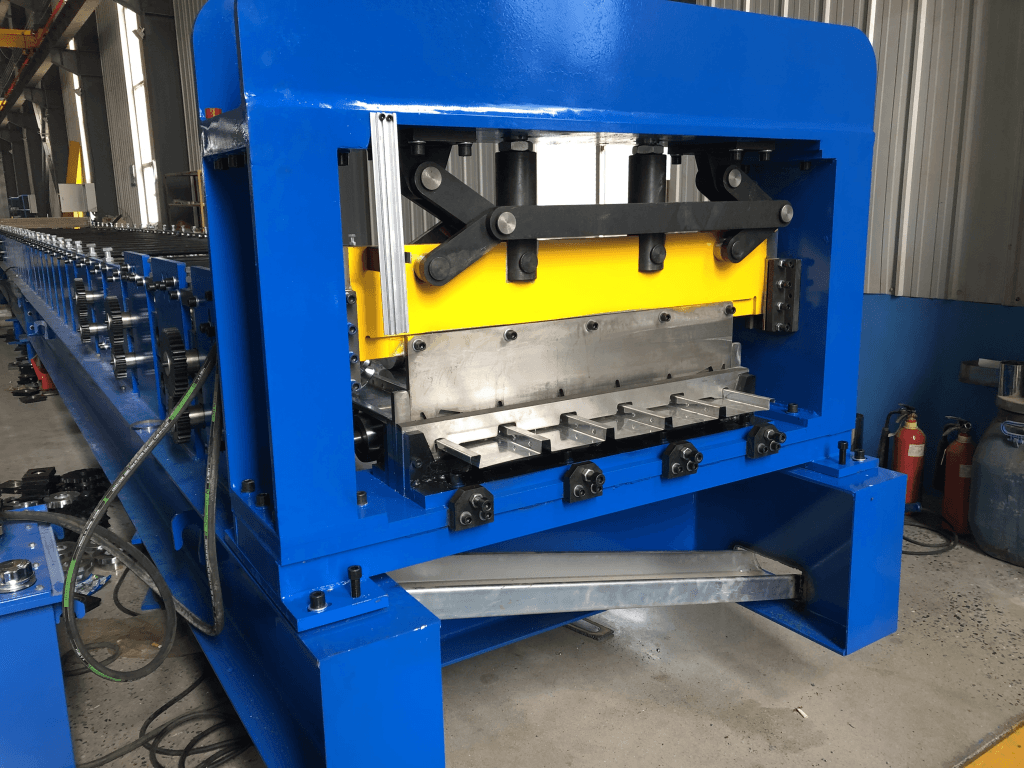

We have developed a dovetail decking roll forming machine specifically for our Malaysian clients, which boasts several key advantages:

1. Precise Cutting: The machine features a 7.5 kW hydraulic cutting system that ensures clean cuts without deformation or burring, capable of cutting material up to 1.6 mm thick.

2. Robust Construction: The machine’s frame is built with 400 # H steel and reinforced with diagonal bracing for enhanced strength and stability during operation and material loading.

3. Enhanced Power: Our machine includes a chain tensioner design to provide additional power to the roller stations, ensuring efficient and consistent performance.

4. Advanced Cooling System: The hydraulic oil pump station is equipped with a large pump box and an integrated cooling system. This feature is crucial for maintaining operational efficiency during prolonged use, preventing the hydraulic oil from overheating. Excessive heat could otherwise lead to a reduction in cutting strength.