1. What is involved in the roll forming procedure?

Roll forming is a continuous technique that transforms sheet metal into a predetermined shape by passing it through a series of matching rollers, with each set making a slight, progressive change to the metal’s form. These incremental modifications accumulate to create a intricate profile. This is different from traditional metal stamping, where the entire part is shaped in one operation.

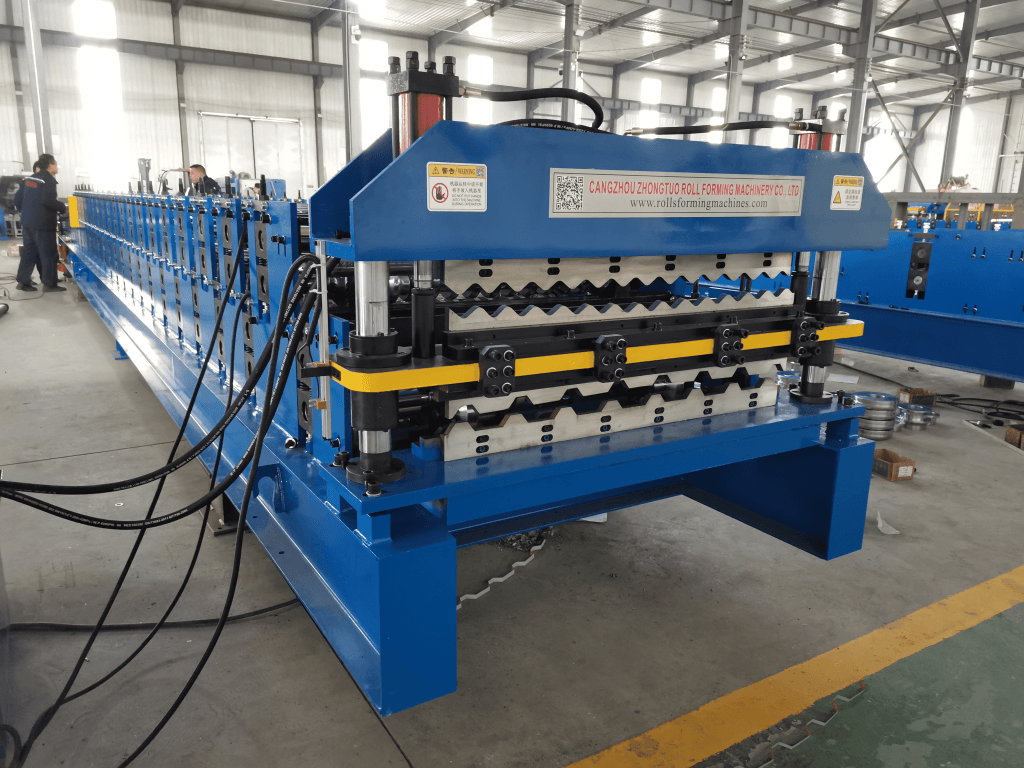

- What is the purpose of a roll forming machine?

Roll forming machines are engineered to convert sheet metal into straight, formed profiles. The process involves feeding a continuous strip of flat metal through a progression of hardened steel rollers, which gradually shape the metal into its final form at each stage of the machine.

3.Our machine can customized with customer’s requirement

ZTRFM has specialized in the production of panel roll forming lines for the past three decades, with our metal panel roll formers being exported to over 150 countries. Our machinery is tailored to meet individual customer specifications, allowing us to create custom roll forming lines such as the R-PANEL, PBR-PANEL, and AG-PANEL for various United States customers. We’ve also developed the TR4 and TR5 panel roll formers for Peru, and the PV4 and PV6 panel roll forming lines for Chile. In total, we boast extensive expertise in the design and manufacture of these machines.

4.You have the flexibility to select according to your needs

We offer a range of choices for the decoiler and collection table on the panel roll forming line. For instance, you can select from a manual decoiler or a hydraulic decoiler. The hydraulic decoilers come in various load capacities, such as 5t, 8t, 10t, and 15t. Additionally, for the collection table, we provide options in terms of length and whether it is automatic or manual.