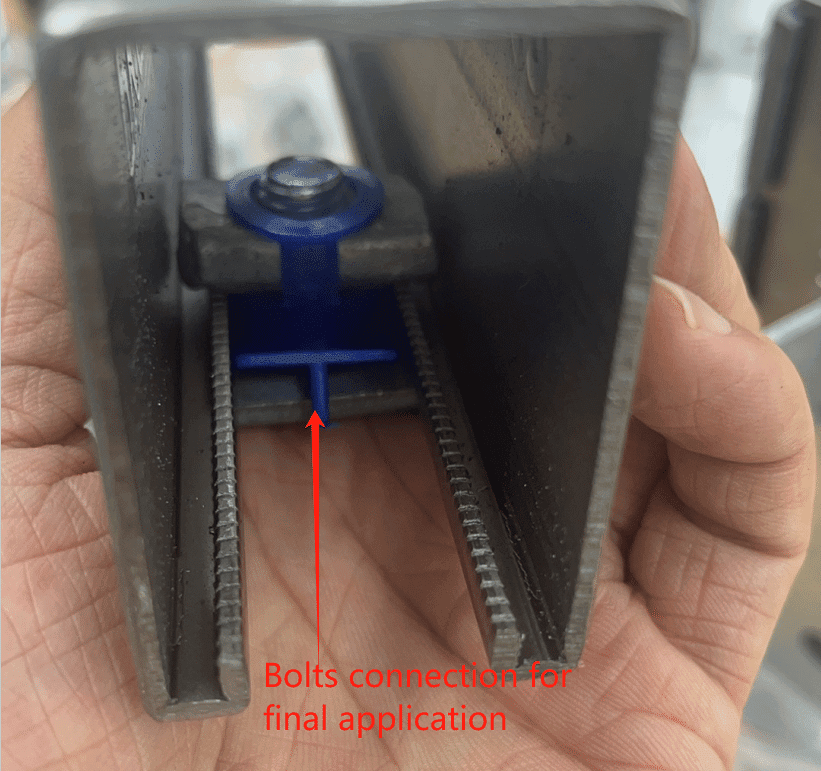

Enhancing the structural integrity of C strut profile machine through precision teeth design is of paramount importance. The quality of the teeth directly affects the product’s functionality, especially in terms of secure bolt connections that should remain stable after assembly. The selection of the right machinery design and tooth-production technique is critical to the machine’s acceptance by the ultimate users.

Different techniques can be utilized to create the teeth in strut profiles, with varying degrees of effectiveness. An optimal technique ensures that the teeth are not only deeper but also correctly positioned at the metal’s summit to optimize frictional engagement. This method also contributes to a longer lifespan for the teethed rollers. Our machinery features a design with roller spacers on the shaft, enabling the adjustment of the teeth position as the rollers experience wear, which extends their useful life.

While other teeth-production methods are available, our evaluation has shown them to be Inferior. I will provide photos of these methods, which we have discontinued in our production of C strut-profile machines.