Grouting Keel is primarily used in light gauge steel integrated housing and represents a new technique for concrete grouting in interior and exterior walls. This method involves adhering a grouting mesh mold to the grouting keel framework and then filling the core with concrete to create a load-bearing wall that offers fire resistance and sound insulation.

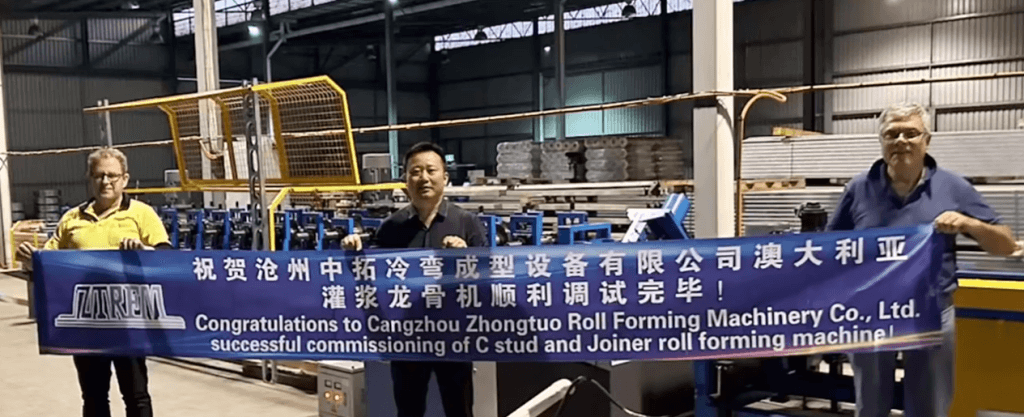

This is a grouting keel machine ordered by an Australian customer, which operates fully automatically from unwinding to forming, cutting, conveying, robotic feeding, punching, and final discharge, without the need for manual labor. The entire machine is equipped with 9 sets of molds, capable of producing various types of grouting keels.

The grouting keel made using hot-dip galvanized technology is resistant to rust and corrosion, effectively preventing wall cracking. It is beneficial for earthquake resistance and reducing the load on vertical load-bearing structures and foundations. The construction speed is fast, and it is easy to install and transport materials. The large kidney-shaped holes are designed for dual casting and to increase concrete flow, offering good waterproofing and reducing noise transmission with its closed cavity structure. The construction process is simple, which shortens the construction period and saves costs, making it an economical and efficient choice.

Grouting keels have broad market prospects in areas such as light gauge steel villas, secondary structures of steel structure buildings, high-rise residential secondary structures, and secondary partition walls in frame stores.